Digital Twin for Optimized Manufacturing Processes

Real-time Monitoring and Enhanced Visibility

Real-time Data Acquisition and Processing

Real-time monitoring in a digital twin environment relies heavily on the continuous acquisition of data from various sources within the manufacturing process. Sensors embedded throughout the production line, from machinery to raw materials, collect a wealth of information regarding temperature, pressure, vibration, and other critical parameters. This data stream, often high-volume and complex, is then processed and analyzed by sophisticated algorithms. This real-time data processing is crucial for identifying anomalies, predicting potential failures, and enabling proactive maintenance interventions.

Effective data processing within the digital twin necessitates robust data pipelines and efficient algorithms. These algorithms must be capable of sifting through the massive influx of data to identify patterns, trends, and outliers that might indicate deviations from normal operating parameters. Furthermore, the processing must be fast enough to respond in real-time, enabling timely interventions and minimizing potential disruptions to the production process.

Enhanced Visualization and Dashboards

A key benefit of real-time monitoring within a digital twin is the ability to visualize the collected data in intuitive and actionable dashboards. These dashboards provide a comprehensive overview of the entire manufacturing process, allowing operators and managers to monitor key performance indicators (KPIs) in real-time. By presenting data in graphical formats, such as charts, graphs, and maps, the digital twin facilitates a quick and easy understanding of the status of various components and processes.

These interactive dashboards are designed to not only display current data but also to highlight potential issues and trends. Advanced features, like predictive modeling and trend analysis, are embedded within these dashboards to provide early warnings of potential problems. This proactive approach enables manufacturers to take preemptive measures, minimizing downtime and maximizing efficiency.

Improved Decision-Making and Optimization

The enhanced visibility afforded by real-time monitoring and data visualization within a digital twin empowers manufacturers to make more informed and timely decisions. By analyzing real-time data and identifying anomalies, operators can quickly address potential issues, preventing production delays and ensuring optimal resource allocation. The digital twin serves as a virtual replica of the physical factory, allowing manufacturers to test different scenarios and strategies without impacting the actual production process.

Furthermore, real-time data analysis can be used to identify bottlenecks and inefficiencies in the manufacturing process. By pinpointing areas of weakness, manufacturers can optimize workflows, reduce waste, and improve overall production efficiency. The data-driven insights provided by the digital twin contribute significantly to achieving greater operational excellence and cost savings in the long run. This is a crucial aspect of the digital twin approach to manufacturing optimization.

Proactive Maintenance and Predictive Analytics

Real-time monitoring facilitates the implementation of proactive maintenance strategies, a critical component of optimizing manufacturing processes. By continuously monitoring equipment performance, the digital twin can predict potential failures well in advance. This allows for scheduled maintenance interventions, preventing unexpected downtime and minimizing costly repairs. Predictive analytics, integrated within the digital twin, can forecast equipment failures based on historical data and real-time sensor readings.

This proactive approach to maintenance is dramatically more effective than reactive maintenance, where issues are addressed only after they have occurred. The result is a significant reduction in unplanned downtime, a rise in equipment lifespan, and a considerable decrease in maintenance costs. These advantages contribute to a more resilient and efficient manufacturing operation, ultimately boosting profitability.

Read more about Digital Twin for Optimized Manufacturing Processes

Hot Recommendations

- Beyond Buzzwords: Real World Applications of Supply Chain Tech

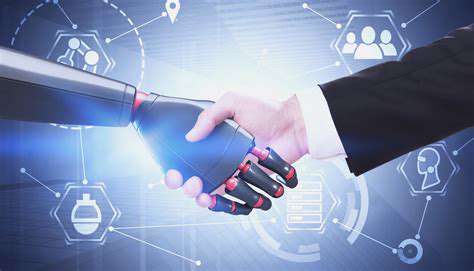

- Digital twin for simulating human robot collaboration scenarios

- The Future of Supply Chain Strategy Development: AI Driven

- Big Data in Supply Chain: Challenges and Opportunities

- Generative AI for Supply Chain Workforce Augmentation

- Simulating the Impact of Supplier Disruptions with Digital Twins

- Sustainable urban logistics planning and policy

- Overcoming Data Fragmentation in Global and Multi Enterprise Supply Chains

- Robotics for cross docking operations: Speeding transit

- Natural language generation for automated weekly supply chain reports