Digital twin for simulating human robot collaboration scenarios

Introduction to Digital Twin Technology

What is a Digital Twin?

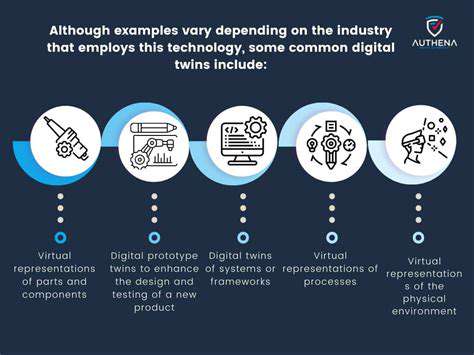

A digital twin is a virtual representation of a real-world entity, process, or system. It's a powerful tool that captures and simulates the characteristics, behavior, and performance of its physical counterpart. This virtual replica can be used to analyze data, predict outcomes, and optimize performance in a safe and controlled environment, without impacting the real-world system.

Essentially, it's a digital mirror of something physical, allowing for experimentation and improvement without real-world consequences. This virtual representation is constantly updated with real-time data from the physical entity, ensuring that the digital twin remains accurate and reflects the current state of the system.

Key Components of a Digital Twin

A digital twin comprises several crucial components. First and foremost is the real-time data acquisition system, which collects data from sensors and other sources related to the physical entity. This data is then fed into a sophisticated model that replicates the system's behavior and characteristics.

Secondary components include simulation capabilities, which allow for testing and optimization scenarios, and visualization tools, which provide a clear and understandable representation of the data and outcomes. Finally, a robust data management system is essential for storing, processing, and analyzing the vast amounts of data generated by the digital twin.

Benefits of Utilizing Digital Twins

Digital twins offer a multitude of benefits across various industries. One significant advantage is the ability to predict potential issues and proactively address them, thereby minimizing downtime and maximizing operational efficiency. This predictive maintenance capability is particularly valuable in industries with complex machinery or critical infrastructure.

Furthermore, digital twins enable better decision-making by providing insights into system behavior and performance under different conditions. This allows for the identification of optimization opportunities and the exploration of various scenarios without affecting the actual system. This ultimately leads to cost savings and improved performance.

Applications Across Industries

Digital twin technology has diverse applications, from manufacturing and healthcare to energy and transportation. In manufacturing, they can optimize production processes, predict equipment failures, and improve supply chain management. In healthcare, digital twins can model patient conditions, predict outcomes, and support personalized treatment plans.

Beyond these sectors, digital twins are revolutionizing urban planning, enabling better infrastructure management and resource allocation. The versatility and potential of digital twins are continuously expanding, opening up new possibilities for innovation and improvement across numerous industries.

Optimizing Human-Robot Collaboration Workflows

Defining Collaboration Workflows

Optimizing human-robot collaboration workflows hinges on a precise understanding of the collaborative tasks and the specific roles of both humans and robots. This involves meticulously documenting the steps involved in each task, identifying critical decision points, and mapping out the communication channels and data exchange protocols. A clear understanding of these workflows allows for the identification of potential bottlenecks and inefficiencies, paving the way for targeted improvements. This detailed analysis is crucial for developing effective simulation models.

Furthermore, the definition phase should encompass consideration of potential variations in task complexity and environmental conditions. Different scenarios might require different levels of human intervention or robot autonomy. Anticipating these variations ensures the flexibility of the workflow, allowing for seamless adaptation to unexpected situations. This proactive approach to workflow design is key to achieving optimal performance in dynamic environments.

Leveraging Digital Twins for Simulation

Digital twins offer a powerful tool for simulating and optimizing human-robot collaboration workflows. By creating a virtual replica of the physical workspace and incorporating models of both human and robot behaviors, we can test various scenarios and evaluate different strategies without the risks and costs associated with real-world experimentation. This allows for iterative improvement of the workflows before implementation in the actual environment.

The simulation capabilities of digital twins are particularly valuable in scenarios involving complex tasks and dynamic environments. For example, a digital twin can simulate the interaction between a human operator and a robotic arm during a manufacturing process, allowing engineers to identify potential collisions or inefficiencies in the movement patterns of the robot and the human. This kind of predictive analysis is vital for optimizing safety and efficiency.

Improving Efficiency and Safety Through Simulation

Through simulations, we can identify and address potential safety hazards and inefficiencies in human-robot collaboration workflows. Analyzing simulated interactions allows for the identification of areas where human-robot communication needs improvement or where safety protocols need reinforcement. The ability to run numerous simulations with varying parameters enables the identification of optimal strategies for task completion, maximizing efficiency and minimizing risks.

By simulating different human-robot interactions, digital twins can help us understand and mitigate the risks associated with human-robot collaboration. Simulations can reveal potential safety hazards, such as the likelihood of collisions or the potential for human error in interacting with the robots. This anticipatory approach enables the development of safer and more reliable collaboration protocols, ultimately improving the overall safety of the workspace.

Furthermore, digital twins can be used to evaluate the impact of different robot functionalities on the overall workflow. This allows for the identification of areas where robots can be better integrated into existing processes and where tasks can be automated more efficiently. This iterative approach allows for continuous improvement of the workflow, leading to increased productivity and better overall performance.

Key Benefits and Future Applications

Enhanced Safety and Risk Mitigation

Digital twins provide a crucial platform for simulating human-robot collaborative tasks in a safe and controlled environment. By virtually replicating the physical workspace and the robot's movements, potential hazards and risks can be identified and mitigated before they occur in the real world. This allows for a more thorough analysis of interactions, reducing the likelihood of accidents and improving the overall safety of the collaborative process. This proactive approach to safety is particularly important in dynamic environments where unpredictable situations can arise.

Improved Training and Skill Development

Training human operators on how to effectively collaborate with robots can be challenging and time-consuming in a real-world setting. Digital twins offer a cost-effective and efficient alternative. Virtual environments allow operators to practice various scenarios, receive immediate feedback, and iterate on their performance without the constraints of real-world limitations or safety concerns. This iterative learning process accelerates skill acquisition and enhances the overall proficiency of the human-robot team.

Furthermore, simulations can be tailored to specific tasks and skill levels, facilitating personalized training programs. This level of customization is almost impossible to achieve in traditional training methods.

Optimization of Workflows and Efficiency

By virtually replicating the entire production process, digital twins can pinpoint bottlenecks, inefficiencies, and areas for improvement in human-robot collaboration workflows. This allows for process optimization, streamlining the tasks performed by both humans and robots, and maximizing overall efficiency. The analysis of real-time data within the digital twin can identify the most efficient sequences for tasks and provide insights into optimizing the arrangement of equipment and resources. This analysis can lead to substantial improvements in productivity.

Predictive Maintenance and Proactive Problem Solving

Digital twins can be instrumental in predicting potential maintenance needs and proactively addressing potential issues before they impact the overall production process. By monitoring the virtual counterparts of physical components and systems, the digital twin can identify patterns and anomalies that might indicate upcoming failures. This predictive capability minimizes downtime, avoids costly repairs, and maximizes the operational lifespan of both human-robot collaborative systems and individual components.

Cost Reduction and Increased Return on Investment

Implementing human-robot collaboration often involves significant initial costs. However, digital twin simulations can help justify these investments by demonstrating the potential return on investment (ROI). Through detailed analysis of simulated scenarios, companies can quantify the projected gains in efficiency, productivity, and safety, providing tangible evidence of the value proposition of the collaboration. This allows for informed decision-making and provides a clear roadmap for maximizing the return on investment. Ultimately, this translates into significant cost reduction and enhanced profitability.

Read more about Digital twin for simulating human robot collaboration scenarios

Hot Recommendations

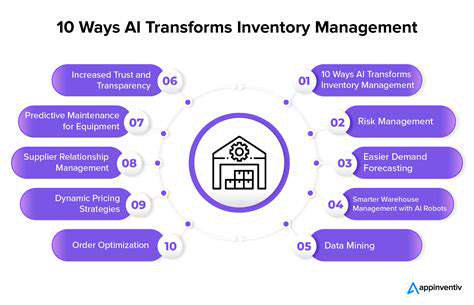

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit