Robotics for cross docking operations: Speeding transit

Optimizing Order Fulfillment through Robotic Sorting and Picking

Streamlining the Picking Process

Efficiently picking orders is crucial for timely delivery and customer satisfaction. Implementing a well-organized picking strategy, such as zone picking or batch picking, can significantly reduce order processing time. This involves carefully planning the layout of the warehouse and optimizing the movement of pickers to minimize travel time between locations. Using barcode scanners or RFID technology can further enhance the speed and accuracy of picking, reducing errors and improving overall productivity.

Utilizing tools like conveyor belts or automated picking systems can also significantly expedite the process. These technologies can automate the movement of items from storage to the packing area, reducing the manual effort required and minimizing the potential for human error. This leads to a more streamlined process and greater accuracy in fulfilling orders.

Optimizing Inventory Management

Maintaining optimal inventory levels is vital for minimizing storage costs and preventing stockouts. Accurate inventory tracking allows businesses to anticipate demand fluctuations and adjust stock levels accordingly. Implementing inventory management software can provide real-time visibility into inventory levels, helping businesses make data-driven decisions to optimize stock levels and prevent costly overstocking or stockouts.

Implementing a robust forecasting model, based on historical sales data and market trends, can help businesses predict future demand and adjust inventory levels accordingly. This proactive approach can minimize the risk of stockouts and ensure that products are available when customers need them, leading to improved customer satisfaction and reduced lost sales.

Improving Packaging and Shipping Procedures

Efficient packaging and shipping procedures are essential for protecting products during transit and ensuring timely delivery. Using appropriate packaging materials and techniques helps ensure that products arrive at their destination in perfect condition, minimizing damage and returns. Streamlining the packaging process with standardized procedures and automated equipment can significantly reduce the time needed for packaging and shipping.

Implementing robust shipping strategies, such as using carrier relationships for optimal pricing and delivery schedules, can also significantly optimize order fulfillment. Choosing the correct shipping method based on the specific needs of each order can reduce costs and improve delivery times.

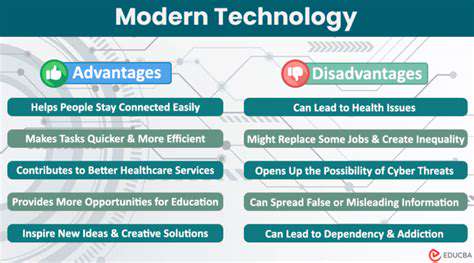

Leveraging Technology for Automation

Integrating technology into the order fulfillment process can automate repetitive tasks and improve accuracy. Utilizing warehouse management systems (WMS) can streamline the entire order cycle, from receiving to shipping. WMS solutions provide real-time visibility into inventory levels, order status, and picking assignments, enabling proactive adjustments and improved efficiency.

Implementing automated guided vehicles (AGVs) or robotic process automation (RPA) can further enhance the efficiency of order fulfillment by automating various tasks. This not only reduces labor costs but also improves the speed and accuracy of order processing.

Customer Relationship Management (CRM) Integration

Integrating CRM systems with order fulfillment processes provides valuable insights into customer preferences and expectations. This allows businesses to tailor the order fulfillment experience to individual customer needs, enhancing customer satisfaction and loyalty. Tracking customer feedback and adjusting procedures based on their input allows companies to continually improve their order fulfillment process.

By closely monitoring order fulfillment metrics and using CRM data to identify trends and patterns, companies can proactively address potential issues and enhance the customer experience. This data-driven approach allows for continuous process improvement and optimization of the entire order fulfillment lifecycle.

Read more about Robotics for cross docking operations: Speeding transit

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit