Big Data in Supply Chain: Challenges and Opportunities

Data Collection and Preparation

Effective data-driven decision-making hinges on the ability to gather and prepare relevant data. This involves identifying the specific data points needed to answer the questions at hand and selecting appropriate sources, which could range from internal databases to external market research reports. Thorough data collection is crucial, as incomplete or inaccurate data can lead to flawed conclusions and ultimately, poor decisions. Careful cleaning and preprocessing of the data are also vital steps. This involves handling missing values, correcting inconsistencies, and transforming the data into a suitable format for analysis. This meticulous preparation ensures that the insights derived from the data are accurate and reliable.

A key aspect of data preparation is data validation. This process ensures that the collected data is consistent with expectations and free of errors. This step is often overlooked, but it is critical to the reliability of the analysis. Validating data helps to minimize the risk of drawing misleading conclusions or making decisions based on faulty information. Furthermore, understanding the context of the data and its limitations is essential for proper interpretation and application in decision-making processes. This understanding will prevent potential biases and provide a more holistic view of the situation.

Analysis and Interpretation

Once the data is collected and prepared, the next crucial step is to analyze it. This involves utilizing various statistical methods, data visualization techniques, and analytical tools to identify patterns, trends, and correlations within the dataset. The goal is to extract meaningful insights that can inform strategic decisions. The analysis process should be driven by clear objectives, and the results should be presented in a way that is easy to understand and interpret by all stakeholders. This includes creating clear visualizations and summaries of findings.

Interpreting the results of the analysis is equally important as performing the analysis itself. It's not enough to simply identify trends; one must understand the underlying causes and implications of those trends. This requires critical thinking and a deep understanding of the business context. By connecting the data insights to the overall business objectives, decision-makers can gain a clearer picture of the potential impact of different actions. The analysis should also consider potential limitations and biases in the data and acknowledge any uncertainty in the conclusions drawn.

Decision Making and Implementation

The final stage in data-driven decision-making is translating the insights into actionable strategies. This involves defining clear objectives, developing specific strategies, and implementing those strategies in a structured and measurable way. Effective strategies are supported by data-driven insights and are designed to achieve specific outcomes aligned with business goals. This stage often requires collaboration among various teams and departments to ensure alignment and buy-in from all stakeholders. It is crucial to communicate the decision-making process and the rationale behind the chosen strategies clearly and concisely.

Monitoring and evaluating the implementation of these strategies is essential. This involves tracking key performance indicators (KPIs) and analyzing the results to determine whether the strategies are achieving the desired outcomes. Continuous monitoring and evaluation allow for adjustments to be made as needed, ensuring that the strategies remain effective and aligned with evolving business needs. By adapting strategies based on data, organizations can ensure that their decisions are always informed and responsive to the changing market and operational conditions.

Overcoming the Challenges of Big Data Implementation

Data Integration and Silos

A significant hurdle in big data implementation within supply chains is the sheer volume and variety of data sources. Companies often operate with disparate systems, each storing data in different formats and structures. This creates data silos, making it extremely difficult, if not impossible, to gain a holistic view of the entire supply chain. Integrating these disparate data sources into a unified platform requires significant effort, specialized expertise, and careful planning. Without a robust and well-defined integration strategy, the benefits of big data remain elusive, and valuable insights are lost.

Furthermore, the sheer volume of data generated by various supply chain processes can overwhelm traditional data management systems. This necessitates the implementation of advanced data warehousing and processing techniques, such as cloud-based solutions, to effectively store, process, and analyze the massive datasets. Overcoming the data integration challenge is crucial for leveraging the potential of big data to improve decision-making and optimize supply chain operations.

Scalability and Technological Infrastructure

Implementing big data solutions in a supply chain requires a robust and scalable technological infrastructure. This includes not only the hardware and software necessary to process and store the data but also the ability to handle increasing volumes of data as the business grows. Companies need to carefully consider the long-term scalability of their infrastructure to avoid bottlenecks and ensure that their systems can adapt to future data growth.

Beyond the hardware, the software and tools required for big data analysis, including data mining, machine learning algorithms, and visualization tools, need to be selected and implemented thoughtfully. This requires expertise in data science, machine learning, and relevant software platforms. Failing to adequately address these technological infrastructure needs can lead to inefficiencies, inaccuracies, and a lack of actionable insights, ultimately hindering the value proposition of big data implementation.

The high cost of implementing and maintaining big data infrastructure is another critical consideration. This includes the cost of hardware, software licenses, skilled personnel, and ongoing maintenance. Carefully evaluating the return on investment (ROI) and aligning big data implementation with strategic business objectives are essential for successful deployment.

Choosing the right tools and technologies is crucial for scalability. Cloud-based solutions often prove beneficial for their scalability and cost-effectiveness. However, data security and compliance issues must be addressed in any cloud-based implementation.

The complexity of integrating different systems and technologies can also present significant challenges. Careful planning and coordination are essential to ensure smooth integration and avoid disruptions to normal supply chain operations.

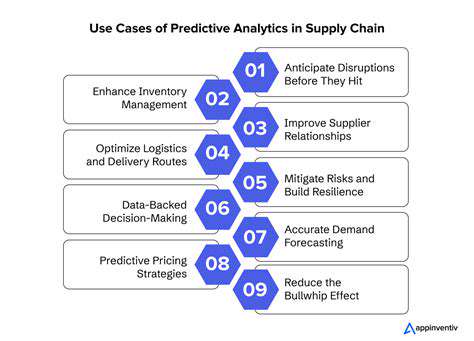

Enhancing Supply Chain Resilience with Predictive Analytics

Improving Forecasting Accuracy

Accurate forecasting is crucial for mitigating supply chain disruptions. By implementing advanced analytics and machine learning algorithms, businesses can significantly improve their ability to predict future demand and supply fluctuations. This proactive approach allows companies to anticipate potential bottlenecks and shortages, enabling them to adjust their production schedules and inventory levels accordingly. This proactive approach will help companies to better manage their resources and maintain a steady flow of goods throughout the supply chain.

Improving data collection methods and incorporating external factors like economic indicators and social trends can significantly enhance the accuracy of forecasting models. This will allow businesses to anticipate potential disruptions and to react more effectively to changes in the market. By understanding the nuances of market fluctuations, businesses can better prepare for challenges and maintain a more resilient supply chain.

Diversifying Supply Sources

Over-reliance on a single supplier is a significant vulnerability in any supply chain. A single point of failure can have devastating consequences, disrupting production and causing significant financial losses. Diversifying supply sources is a critical strategy for enhancing resilience. This involves establishing relationships with multiple suppliers, potentially in different geographic locations, to reduce dependence on any one entity. This diversification approach can help to reduce the impact of unexpected disruptions to a single supplier.

By spreading risk across multiple suppliers, businesses can minimize the impact of disruptions on their operations. This means that if one supplier faces issues, businesses can still obtain materials or components from other sources. A diversified supply chain is a more robust supply chain and is less prone to disruptions.

Strengthening Collaboration and Communication

Effective communication and collaboration among all stakeholders throughout the supply chain are essential for resilience. This includes not only internal departments but also suppliers, distributors, and customers. Clear and consistent communication channels are vital for sharing information about potential disruptions, such as natural disasters or geopolitical events, allowing for proactive adjustments and mitigating the impact of potential issues. Open communication fosters trust and understanding among all participants, enabling faster response times and more effective problem-solving.

Establishing clear communication protocols and fostering strong relationships with key partners can significantly enhance responsiveness during times of crisis. This proactive approach enables businesses to work together to overcome obstacles and maintain the flow of goods and services. By prioritizing collaboration and communication, companies can build a more resilient and adaptable supply chain.

Read more about Big Data in Supply Chain: Challenges and Opportunities

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit