Vertical Mushroom Farming Business for Eco Couples

Understanding Your Niche

Successful vertical mushroom farming begins with deep market understanding. Are you targeting high-end restaurants needing gourmet varieties? Health-conscious consumers seeking medicinal mushrooms? Identifying your ideal customer's specific needs determines every subsequent decision from species selection to marketing approach. Thorough competitor analysis reveals market gaps - perhaps nobody locally grows specialty lion's mane mushrooms, creating your unique opportunity.

Defining Your Value Proposition

Your farm's value extends beyond just selling mushrooms. Maybe you offer ultra-fresh harvests delivered within hours of picking. Perhaps you specialize in rare varieties unavailable elsewhere. Clear differentiation makes your operation memorable and justifies premium pricing. Consider value-added products like mushroom jerky or extracts to diversify revenue streams.

Crafting a Unique Selling Proposition (USP)

Your USP should complete this sentence: Unlike other mushroom farms, we... Maybe you use 100% renewable energy, or offer grow-your-own kits for home enthusiasts. This distinctive edge becomes the cornerstone of all marketing efforts.

Developing a Robust Marketing Strategy

Effective mushroom marketing combines education and storytelling. Blog posts about health benefits, cooking demos featuring your products, and farm tours build connections with customers. Social media excels for visually showcasing beautiful mushrooms and behind-the-scenes growing processes.

Building a Scalable Business Model

Plan for growth from day one. Will you expand vertically with more layers, or horizontally by adding locations? Automation technologies like climate control systems and harvesting robots can maintain quality while reducing labor costs as you scale.

Beyond the Basics: Choosing Your Mushroom Species and Cultivating Techniques

Understanding Mushroom Species Diversity

Each mushroom species presents unique cultivation challenges and rewards. Oyster mushrooms grow vigorously on straw, making them ideal beginners' projects. Shiitakes demand hardwood substrates but command higher prices. Starting with 2-3 reliable varieties builds confidence before attempting finicky species like morels.

Optimizing Substrate Selection and Preparation

Substrate choice dramatically affects yields. Coffee grounds work well for oysters, while shiitakes prefer oak sawdust. Proper pasteurization eliminates competitors while preserving nutrients - a critical step many beginners overlook.

Controlling Environmental Factors for Optimal Growth

Precision environmental control separates hobbyists from professionals. King oysters need 60-70°F with 85-90% humidity, while nameko mushrooms thrive in cooler 50-60°F conditions. Investing in quality sensors and automation pays dividends in crop consistency.

Implementing Proper Spawn Inoculation Techniques

Inoculation method affects colonization speed and contamination risks. Grain spawn works well for bulk substrates, while dowel spawn simplifies log cultivation. Maintaining sterile technique during inoculation prevents costly failures.

Monitoring and Maintaining Hygiene During Cultivation

Rigorous cleanliness separates successful growers from frustrated ones. Regular alcohol sterilization of tools, HEPA-filtered air flow, and immediate removal of contaminated blocks preserve crop health.

Harvesting and Post-Harvest Handling for Quality

Timing harvests perfectly maximizes shelf life. Oysters should be picked just before cap edges flatten, while portobellos benefit from slightly later harvesting. Proper cold storage immediately after picking preserves texture and flavor that discerning buyers appreciate.

When planning major cultivation expansions, consider consulting experienced mushroom farm designers. Their expertise in workflow optimization and climate system design can prevent costly mistakes.

Financial Planning and Sustainability Considerations: A Holistic Approach

Investment Strategies for a Sustainable Future

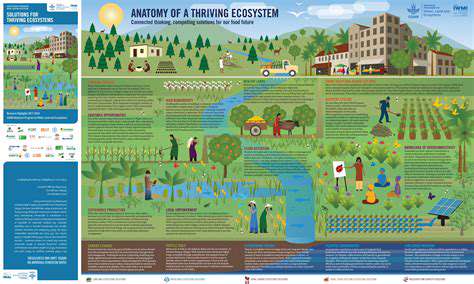

Modern mushroom farming intersects with sustainable investing principles. Vertical systems' energy efficiency and small footprint align with environmental priorities that attract eco-conscious investors. Tracking water and electricity use per pound of mushrooms produced creates compelling sustainability metrics.

Integrating ESG Factors into Your Financial Plan

Evaluate suppliers through an ESG lens - do they use sustainable packaging? Provide fair wages? Renewable energy credits can offset power usage, while composting waste creates additional revenue streams. Transparent sustainability reporting builds trust with discerning customers willing to pay premium prices.

Read more about Vertical Mushroom Farming Business for Eco Couples

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit