Real Time Data for Adaptive Supply Chain Networks

Building a Resilient Supply Chain Through Data-Driven Decisions

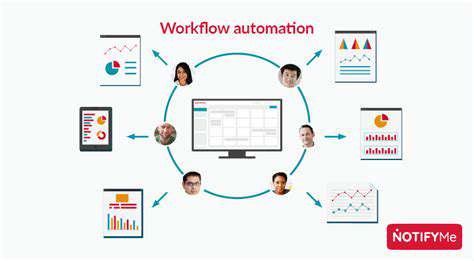

Data Collection and Integration

A robust supply chain hinges on the ability to collect and integrate data from various sources. This encompasses everything from real-time sensor readings on production lines to detailed shipping updates from logistics providers. Effective data integration requires a well-defined architecture, ensuring seamless data flow across departments and systems. By connecting disparate data points, businesses gain a holistic view of their operations, enabling proactive identification of potential bottlenecks and inefficiencies.

Different data sources, including warehouse management systems (WMS), enterprise resource planning (ERP) systems, and transportation management systems (TMS), need to communicate effectively. This integration process must also account for data quality, ensuring accuracy and reliability of the information used for decision-making.

Predictive Analytics for Proactive Measures

Implementing predictive analytics is crucial for anticipating potential disruptions and proactively mitigating risks. By analyzing historical data, current trends, and external factors, businesses can forecast demand fluctuations, identify potential supply shortages, and anticipate disruptions in the global market. This allows for preemptive measures to be put in place, minimizing the impact of unforeseen events.

Sophisticated algorithms can analyze patterns and anomalies within the data, offering valuable insights into potential future problems. This proactive approach is essential for building a resilient supply chain capable of adapting to changing circumstances.

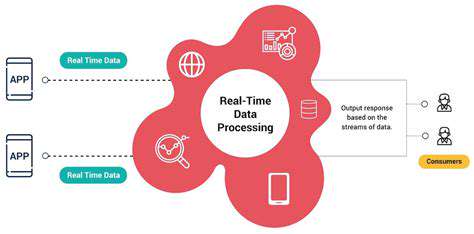

Real-Time Visibility and Monitoring

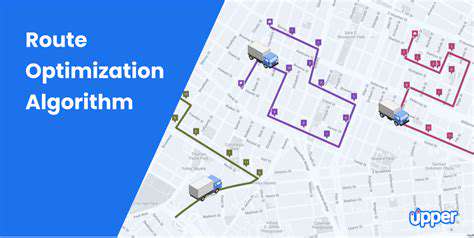

Real-time visibility into every stage of the supply chain is paramount. This means tracking goods from the moment they are manufactured or acquired to their final delivery to the customer. By monitoring inventory levels, production schedules, and transportation routes in real time, businesses gain a clear understanding of where goods are, when they are expected to arrive, and any potential delays. This real-time information allows for rapid response to issues, minimizing downtime and ensuring smooth operations.

Demand Forecasting and Inventory Optimization

Accurate demand forecasting is essential for optimizing inventory levels and minimizing storage costs. Data-driven forecasting models can analyze historical sales data, market trends, and external factors to predict future demand. This allows businesses to maintain optimal inventory levels, avoid stockouts or overstocking, and ensure that the right products are available in the right quantities at the right time. Effective inventory management, empowered by data, directly translates into cost savings and improved customer satisfaction.

Risk Assessment and Mitigation Strategies

Data analysis allows for a comprehensive risk assessment of the supply chain. Identifying potential disruptions, such as natural disasters, geopolitical instability, or supplier failures, is crucial for developing effective mitigation strategies. By evaluating historical data and analyzing current trends, businesses can proactively identify and address potential vulnerabilities in their supply chain. This data-driven approach allows for the development of contingency plans and alternative sourcing strategies, ensuring business continuity in times of crisis.

Improved Communication and Collaboration

Effective communication and collaboration across all stakeholders in the supply chain are vital for resilience. Data-driven insights can facilitate better communication by providing real-time updates on order status, delivery schedules, and potential disruptions. This transparency fosters trust and collaboration between suppliers, manufacturers, distributors, and customers. Data sharing protocols and improved communication tools can streamline decision-making, leading to faster problem resolution and better overall supply chain performance.

Read more about Real Time Data for Adaptive Supply Chain Networks

Hot Recommendations

- Beyond Buzzwords: Real World Applications of Supply Chain Tech

- Digital twin for simulating human robot collaboration scenarios

- The Future of Supply Chain Strategy Development: AI Driven

- Big Data in Supply Chain: Challenges and Opportunities

- Generative AI for Supply Chain Workforce Augmentation

- Simulating the Impact of Supplier Disruptions with Digital Twins

- Sustainable urban logistics planning and policy

- Overcoming Data Fragmentation in Global and Multi Enterprise Supply Chains

- Robotics for cross docking operations: Speeding transit

- Natural language generation for automated weekly supply chain reports