The Role of Big Data Analytics in Supply Chain Predictive Sourcing

Real-World Applications and Future Trends

Real-World Supply Chain Optimization

Big data analytics is revolutionizing supply chain management by enabling companies to gain a deeper understanding of their operations. By analyzing vast amounts of data from various sources, including sales figures, inventory levels, transportation costs, and weather patterns, businesses can identify bottlenecks, predict potential disruptions, and optimize their logistics strategies. This leads to increased efficiency, reduced costs, and improved customer satisfaction. For example, real-time tracking of shipments allows for proactive adjustments in case of delays, minimizing potential stockouts and lost revenue.

Demand Forecasting Accuracy

Historically, demand forecasting was often based on limited data and assumptions, leading to inaccuracies and inefficiencies. Big data analytics, with its ability to process vast datasets, significantly enhances the accuracy of demand forecasting models. This allows businesses to anticipate future demand fluctuations, optimize inventory levels, and avoid overstocking or understocking situations. Improved forecasting translates into lower storage costs and reduced risk of lost sales due to stockouts.

The detailed insights gleaned from historical data, coupled with external factors like social media trends and economic indicators, lead to significantly more precise predictions about future demand. This results in a more agile and responsive supply chain.

Improved Inventory Management

Big data analytics provides invaluable insights into inventory levels and patterns. By analyzing data related to sales, lead times, and supplier performance, companies can optimize their inventory levels. This reduces holding costs, minimizes the risk of stockouts, and prevents overstocking, thereby maximizing the return on investment in inventory. Real-time data analysis allows for a more dynamic approach to inventory management, reacting swiftly to changing demand and supply conditions.

Enhanced Supplier Relationship Management

Understanding supplier performance is crucial for a smooth supply chain. Big data analytics allows companies to monitor supplier performance metrics, track delivery times, and identify potential risks. This facilitates proactive communication and negotiation, leading to stronger, more reliable supplier relationships. By analyzing data on past performance, companies can identify and mitigate potential issues before they affect the supply chain.

Predictive Maintenance and Risk Mitigation

Big data analytics can predict equipment failures in the supply chain, such as machinery breakdowns or transportation disruptions. This predictive capability allows for proactive maintenance and risk mitigation strategies. By identifying potential problems early, companies can minimize downtime and avoid costly disruptions to their operations. This proactive approach ensures a more resilient and reliable supply chain.

Personalized Customer Experiences

Big data analytics isn't just about internal supply chain processes; it also helps companies understand their customers better. Analyzing customer data, including purchase history, preferences, and feedback, allows businesses to tailor their offerings and improve their logistics in response to customer needs. Companies can personalize the delivery experience, offering options like scheduled delivery slots or alternative delivery locations to meet individual customer preferences. These personalized experiences enhance customer satisfaction and loyalty.

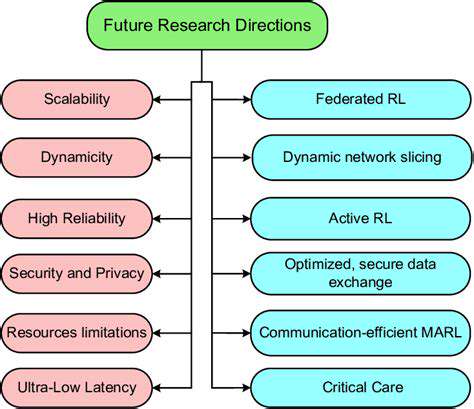

Future Trends in Big Data Analytics

The future of big data analytics in supply chains is bright, with exciting advancements on the horizon. Expect to see more sophisticated algorithms and machine learning models being used to further improve forecasting accuracy and optimize processes. Real-time data integration will become even more prevalent, allowing for instant responses to changing circumstances and improved visibility across the entire supply network. The integration of artificial intelligence (AI) will automate many tasks, optimizing the efficiency and responsiveness of the supply chain and driving even greater cost savings.

Read more about The Role of Big Data Analytics in Supply Chain Predictive Sourcing

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit