The Future of AI in Supply Chain Optimization Algorithms

Predictive analytics is rapidly transforming industries across the globe, empowering businesses to make more informed decisions based on anticipated future outcomes. It's not just about looking at historical data; it's about using sophisticated algorithms and statistical models to identify patterns and trends that can forecast future events. This allows companies to anticipate market shifts, optimize resource allocation, and potentially mitigate risks.

By leveraging vast datasets and advanced analytical techniques, predictive analytics enables businesses to gain a deeper understanding of their customers, markets, and operations. This deeper understanding leads to better strategies, more effective resource allocation, and ultimately, increased profitability. This shift from reactive to proactive decision-making is revolutionizing how businesses operate in today's dynamic environment.

Key Applications of Predictive Analytics

Predictive analytics finds applications in a wide array of fields. In retail, it helps predict customer demand, optimize inventory management, and personalize marketing campaigns. In finance, it aids in fraud detection, risk assessment, and investment strategies. Healthcare leverages predictive analytics to identify patient risks, personalize treatment plans, and improve operational efficiency.

The potential applications are truly limitless, impacting virtually every sector. From manufacturing to agriculture, predictive analytics is revolutionizing the way businesses operate and compete in the global market. This ability to foresee future trends is critical for maintaining a competitive edge in today's complex business environment.

The Power of Data in Predictive Modeling

At the heart of predictive analytics lies the power of data. The quality and quantity of data directly impact the accuracy and reliability of the predictions. Businesses must invest in robust data collection, storage, and management systems to ensure that the data used for predictive modeling is accurate, comprehensive, and relevant.

The right data, combined with sophisticated algorithms, enables predictive models to identify intricate patterns and relationships that would otherwise remain hidden. This data-driven approach allows businesses to anticipate market shifts, optimize operations, and ultimately drive growth and innovation.

Challenges and Considerations in Implementing Predictive Analytics

While the potential benefits of predictive analytics are significant, implementing these systems can present challenges. Data quality issues, the need for skilled data scientists, and the potential for algorithmic bias must be carefully addressed.

Ensuring data accuracy and consistency is crucial for reliable predictions. Furthermore, building and maintaining these models requires specialized expertise. Careful consideration should also be given to potential biases within the data and algorithms themselves to guarantee fair and unbiased outcomes. These considerations are essential for successful implementation.

The Future of Predictive Analytics

The future of predictive analytics is bright, with advancements in machine learning and artificial intelligence promising even more sophisticated and accurate predictions. As technology continues to evolve, the potential for predictive analytics to transform industries will only grow stronger. This technology will continue to become more accessible and integrated into everyday business operations.

Predictive analytics will play an increasingly important role in shaping business strategies, driving innovation, and optimizing resource allocation. From personalized recommendations to proactive risk management, the potential applications are wide-ranging and continue to evolve with technological advancement.

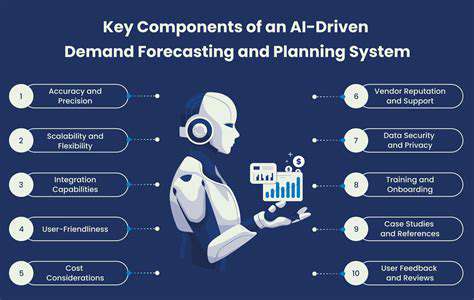

AI-Powered Demand Forecasting for Enhanced Accuracy

Improving Accuracy and Efficiency

AI-powered demand forecasting significantly enhances the accuracy of predictions by leveraging vast datasets and complex algorithms. This allows businesses to anticipate future demand with greater precision, leading to optimized inventory management and reduced waste. By incorporating real-time data and market trends, AI models can identify subtle patterns and anomalies that might be missed by traditional methods. This enhanced accuracy translates directly to cost savings and increased profitability.

The efficiency gains from AI-driven demand forecasting are substantial. Automated processes streamline the forecasting process, reducing manual labor and freeing up valuable time for other critical tasks. This automation translates into quicker turnaround times for critical decisions, enabling businesses to respond more effectively to shifts in market demand.

Understanding Customer Behavior

AI models can analyze massive amounts of customer data, including purchase history, browsing behavior, and demographics, to identify patterns and predict future purchasing trends. This deep understanding of customer preferences allows companies to tailor their products and services more effectively, ultimately driving sales and customer loyalty.

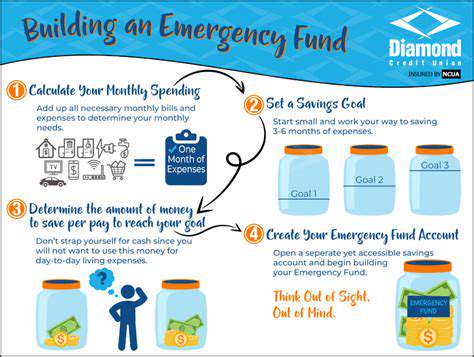

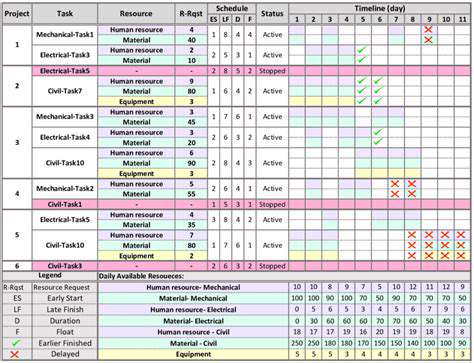

Optimizing Inventory Management

Accurate demand forecasts enable businesses to optimize their inventory levels. By predicting the precise quantity of products needed at specific times, companies can avoid stockouts and overstocking. This leads to significant cost savings, as companies avoid the expense of holding excess inventory and the potential losses associated with lost sales due to stockouts. Precise inventory management minimizes the risk of holding excess inventory and maximizes the availability of products when and where they are needed.

Reducing Operational Costs

By minimizing stockouts and overstocking, AI-powered demand forecasting directly contributes to reduced operational costs. This includes lower warehousing costs, reduced waste, and minimized the cost of lost sales opportunities. Companies can allocate resources more effectively knowing that their inventory levels are precisely aligned with anticipated demand.

Enhancing Supply Chain Efficiency

Accurate demand forecasts provide critical visibility into the supply chain, enabling proactive adjustments to optimize production and distribution. Early identification of potential disruptions, such as supplier shortages or unexpected demand spikes, allows companies to take preventative measures and mitigate potential risks. This enhanced visibility and responsiveness lead to a more agile and efficient supply chain, ultimately improving overall operational performance.

Improving Forecasting Accuracy over Time

AI models continuously learn and adapt to new data and trends. This iterative learning process leads to increasing accuracy in demand forecasting over time. As the model processes more data, it refines its algorithms, resulting in more precise predictions and a more reliable understanding of future demand. This ongoing refinement ensures that forecasting accuracy remains high, even as market conditions evolve. The dynamic nature of AI makes it a valuable tool for adapting to changing market conditions.

Optimizing Logistics and Transportation Through AI

Streamlining Supply Chains

Optimizing logistics and transport involves a multifaceted approach to streamlining supply chains. This includes identifying bottlenecks and inefficiencies in the movement of goods, from raw materials to the final consumer. A key element is analyzing transportation routes and modes to determine the most cost-effective and time-efficient options. Efficient supply chains are critical for businesses to maintain profitability and meet customer demand.

Modern technology plays a significant role in this process. Real-time tracking systems and data analytics tools allow for better visibility into inventory levels, transportation schedules, and potential disruptions. This real-time insight enables proactive adjustments and minimizes delays, ultimately improving overall supply chain performance.

Route Optimization Techniques

Effective route optimization is paramount in reducing transportation costs and delivery times. This involves considering factors such as distance, traffic patterns, fuel consumption, and driver availability. Advanced algorithms and software tools can analyze these variables and generate optimal routes, minimizing fuel costs and maximizing delivery efficiency.

Geographic Information Systems (GIS) can be invaluable. They provide detailed maps and data for route planning, incorporating real-time traffic information and identifying potential delays. This results in more efficient delivery schedules and reduces the overall transportation costs.

Transportation Mode Selection

Choosing the most appropriate transportation mode for a given shipment is crucial. Factors to consider include the type of goods being transported, delivery deadlines, and budget constraints. Understanding the characteristics of each mode – trucking, rail, air, or sea – and their respective strengths and weaknesses is vital.

For example, air freight is ideal for time-sensitive deliveries, while sea freight is often more economical for bulk shipments over longer distances. A careful assessment of these factors will result in a more efficient and cost-effective solution.

Inventory Management and Warehousing

Effective inventory management and warehousing strategies are critical components of optimized logistics. This involves optimizing storage space, implementing efficient picking and packing procedures, and ensuring timely order fulfillment. A well-organized warehousing system can significantly reduce storage costs and improve order accuracy.

Maintaining accurate inventory records is essential. This allows for better forecasting of demand and minimizes the risk of stockouts or excess inventory. Inventory management directly impacts the overall cost of goods and the ability to meet customer expectations.

Technological Advancements in Logistics

Technological advancements are revolutionizing the logistics industry. From automated guided vehicles (AGVs) in warehouses to advanced tracking systems, technology is improving efficiency and reducing costs. These innovations enable real-time visibility and control over shipments, leading to significant improvements in delivery times and reduced errors.

Sustainability and Ethical Considerations

Modern logistics must incorporate sustainability and ethical considerations. Companies are increasingly focusing on reducing their environmental impact by utilizing eco-friendly transportation options, minimizing fuel consumption, and optimizing packaging. This is critical for long-term viability and positive public perception.

Ethical practices, including fair labor standards and responsible sourcing, are becoming increasingly important. Consumers are increasingly aware of the ethical implications of their purchasing decisions, and businesses must respond with responsible practices throughout their supply chains.

Customer Relationship Management (CRM) in Logistics

Effective communication and transparency are crucial for maintaining strong customer relationships in logistics. Keeping customers informed about shipment progress, providing clear communication channels, and addressing any issues promptly are vital for building trust. Strong customer relationships are vital for long-term business success in a competitive market.

The Future of AI in Supply Chain Optimization: Beyond the Algorithms

AI-Powered Predictive Analytics for Proactive Decision-Making

AI algorithms are rapidly evolving, moving beyond basic forecasting to predictive analytics that can anticipate potential disruptions in the supply chain. By analyzing vast datasets encompassing historical order patterns, weather forecasts, and even social media trends, AI can identify potential bottlenecks, shortages, or demand fluctuations well in advance. This proactive approach allows businesses to implement mitigation strategies, such as adjusting production schedules, rerouting shipments, or procuring alternative materials, minimizing the impact of unforeseen events and ensuring consistent supply.

This proactive approach is crucial in today's rapidly changing global landscape. Unpredictable events such as natural disasters, geopolitical instability, and even unexpected shifts in consumer preferences can severely disrupt supply chains. Predictive analytics empowers businesses to anticipate these challenges and react swiftly, maintaining operational efficiency and minimizing financial losses.

Intelligent Automation for Enhanced Efficiency

AI-driven automation is poised to revolutionize various aspects of supply chain operations. From automating order fulfillment and inventory management to optimizing warehouse logistics and transportation, AI can streamline processes, reduce manual errors, and increase overall efficiency. This automation not only boosts productivity but also frees up human resources to focus on more strategic tasks, leading to a more agile and responsive supply chain.

Personalized Customer Experiences Through Data Insights

AI can glean valuable insights from customer data, enabling businesses to tailor their supply chain strategies to meet individual customer needs. By analyzing purchase history, preferences, and even browsing behavior, AI can anticipate customer demands and optimize inventory levels for specific regions or customer segments. This personalized approach improves customer satisfaction and loyalty, fostering stronger relationships with clients.

Optimizing Transportation and Logistics

AI algorithms can optimize transportation routes, reduce fuel consumption, and minimize delivery times, leading to significant cost savings. Real-time tracking, dynamic routing, and predictive maintenance capabilities enhance the efficiency of transportation networks. AI-powered logistics platforms can also improve visibility and transparency throughout the entire supply chain, enabling stakeholders to monitor shipments and address potential delays or issues efficiently.

Ethical Considerations and Responsible AI Implementation

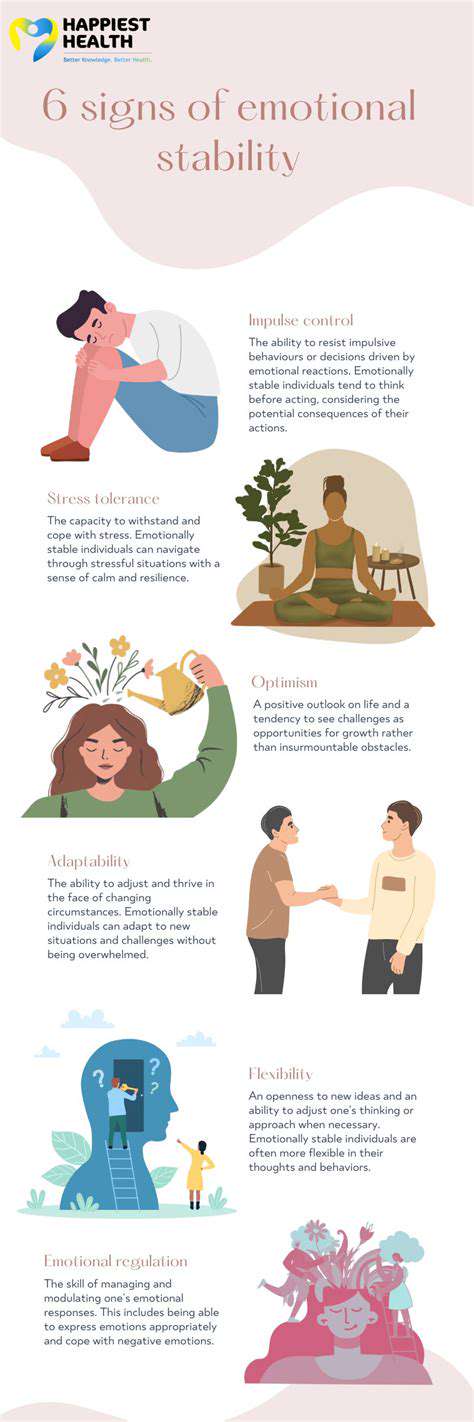

The integration of AI in supply chains raises important ethical considerations, particularly regarding data privacy and algorithmic bias. It's crucial to ensure that AI systems are trained on diverse and representative datasets to avoid perpetuating existing biases. Moreover, transparent and accountable AI implementation is essential to maintain trust and build confidence among stakeholders. Robust ethical frameworks and guidelines are necessary to ensure that AI is used responsibly and ethically throughout the supply chain.

The Role of Human Expertise in the AI-Driven Future

Despite the remarkable potential of AI, human expertise remains essential in the supply chain optimization process. AI tools can automate repetitive tasks, but human judgment, creativity, and adaptability are crucial for handling unexpected situations, navigating complex challenges, and making critical decisions. The future of supply chain optimization lies in a collaborative approach, where AI complements human capabilities, enabling businesses to achieve unprecedented levels of efficiency, resilience, and adaptability.