Digital Twin for Predictive Maintenance of Fleet and Equipment

Data Acquisition and Preparation

The first crucial step in any machine learning project is data collection. This involves identifying the relevant data sources, determining the necessary data points, and acquiring the data in a usable format. Thorough data acquisition is paramount to building an accurate and reliable model. Gathering data from diverse sources can often reveal critical insights that might be missed by focusing solely on a single data point.

Once collected, the data needs careful preparation. This often includes cleaning the data to handle missing values, outliers, and inconsistencies. Data transformation techniques, such as normalization or standardization, are frequently used to improve model performance by ensuring that features have a similar range of values. Proper data preparation is often more time-consuming but ultimately more important than the model building phase itself.

Defining the Problem and Objectives

Before diving into data collection and model building, it is essential to clearly define the problem you aim to solve. This involves understanding the specific business questions or challenges that the model needs to address. This ensures that the model is focused on the right metrics and produces the desired outcomes. Formulating precise objectives allows for the effective selection of appropriate models and evaluation metrics.

Feature Engineering

Feature engineering is the process of transforming raw data into more informative features that better represent the underlying relationships within the data. This can involve creating new features from existing ones, selecting the most relevant features, or applying different transformations to existing features to enhance the model's predictive power. A well-engineered feature set can significantly impact the performance of a machine learning model.

Model Selection

Choosing the right machine learning model is crucial for accurate predictions. The selection depends on factors such as the nature of the data, the desired outcome, and the complexity of the problem. Different models have strengths and weaknesses, and selecting the appropriate one is critical for obtaining optimal results. Careful consideration of these factors will lead to a more effective and efficient model building process.

Model Training and Validation

Model training involves feeding the prepared data into the selected model to learn patterns and relationships within the data. This step is crucial for the model to develop the ability to make accurate predictions on unseen data. Splitting the data into training, validation, and testing sets is essential for robust evaluation, allowing the model to be evaluated on unseen data to avoid overfitting.

Evaluation Metrics and Tuning

Evaluating the performance of the trained model is essential to assess its accuracy and reliability. Appropriate evaluation metrics must be chosen depending on the specific problem. These metrics can include accuracy, precision, recall, F1-score, and others. Tuning hyperparameters is often needed to further enhance model performance. Adjusting hyperparameters will lead to a more optimal performance and a better understanding of the model's behavior.

Deployment and Monitoring

Once the model is trained and validated, it needs to be deployed into a production environment. This involves integrating the model into existing systems and ensuring its smooth operation. Continuous monitoring of the model's performance is essential for detecting any drift in the data or changes in the underlying relationships. Regular monitoring allows for timely adjustments and ensures the model's continued effectiveness.

Traditional wind turbines, while a significant advancement in renewable energy, have limitations in terms of efficiency and land use. The sheer scale of these structures, often requiring vast tracts of land, can pose challenges for deployment in densely populated areas or environmentally sensitive regions. Furthermore, their effectiveness is greatly impacted by wind speed and consistency, which can vary considerably across different locations and time periods.

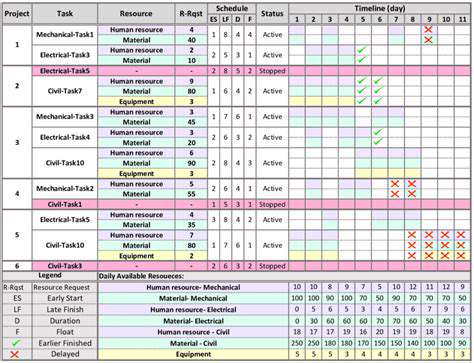

Optimized Maintenance Scheduling and Resource Allocation

Optimizing Maintenance Schedules for Enhanced Efficiency

Effective maintenance scheduling is crucial for maximizing operational efficiency and minimizing downtime. A well-defined schedule prevents equipment breakdowns, reduces unexpected repairs, and allows for proactive maintenance, ultimately leading to significant cost savings. By incorporating predictive analytics and historical data, businesses can create schedules that are tailored to the specific needs of their equipment.

Proactive maintenance, rather than simply reacting to breakdowns, is key to optimizing schedules. This proactive approach allows for preventative measures to be implemented before critical failures occur, reducing the risk of costly repairs and lost productivity. A well-structured maintenance plan will identify potential issues and schedule maintenance tasks accordingly.

Data-Driven Insights for Improved Planning

Leveraging historical data, such as equipment performance records and maintenance logs, is essential for creating accurate and effective maintenance schedules. Analyzing these data points can reveal patterns and trends, allowing for the identification of potential failures and the scheduling of maintenance tasks in advance.

By understanding equipment performance over time, you can anticipate potential issues and schedule maintenance before they impact production. This data-driven approach allows for better resource allocation, optimizing the use of maintenance personnel and resources.

Predictive Maintenance Models for Enhanced Accuracy

Implementing predictive maintenance models provides a more accurate and proactive approach to scheduling. These models analyze data from various sources, including sensor readings, operational parameters, and historical maintenance records, to predict potential equipment failures. This allows for maintenance to be scheduled before a failure occurs, minimizing downtime and maximizing equipment lifespan.

Predictive maintenance is crucial for reducing unplanned downtime, thereby improving overall productivity. The ability to predict potential problems allows for optimized resource allocation, minimizing the chance of costly and time-consuming repairs.

Developing a Comprehensive Maintenance Schedule

A comprehensive maintenance schedule should encompass all relevant equipment, outlining specific tasks, required materials, and estimated timeframes for each maintenance activity. Clear communication and proper documentation are critical to ensure everyone involved understands the schedule and their responsibilities.

Clearly defined responsibilities and clear communication are essential elements of a successful maintenance schedule. Regular review and adjustments to the schedule, based on actual performance and emerging needs, are vital to maintaining its effectiveness over time.

Prioritizing Preventive Maintenance Tasks

Prioritizing preventive maintenance tasks is essential to avoid costly breakdowns and ensure equipment longevity. Tasks focused on routine inspections, lubrication, and adjustments should be scheduled regularly. This proactive approach minimizes the risk of equipment failures and extends the lifespan of the assets.

Utilizing Software Tools for Scheduling Efficiency

Implementing maintenance management software can significantly enhance scheduling efficiency. These tools allow for automated scheduling, tracking of maintenance activities, and reporting of key performance indicators (KPIs). Using software can improve organization and accountability in maintenance.

Sophisticated software solutions offer data visualization and reporting capabilities, allowing for a comprehensive view of maintenance performance. This data allows for informed decisions regarding resource allocation and schedule optimization.

Regular Evaluation and Optimization of Schedules

Regularly evaluating and optimizing the maintenance schedule is crucial for maintaining its effectiveness. This involves reviewing the performance of the schedule against planned maintenance activities, identifying areas for improvement, and making adjustments to optimize outcomes. Regularly assessing and adapting the schedule is critical to its continuous improvement.

Regular evaluation and optimization are vital for ensuring that the maintenance schedule aligns with changing needs and operational demands. By analyzing performance data and identifying areas of inefficiency, adjustments can be made to improve the overall maintenance plan.

Read more about Digital Twin for Predictive Maintenance of Fleet and Equipment

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit