Simulating the Impact of New Technologies on Supply Chain Performance

Selecting Appropriate Simulation Models

Choosing the Right Simulation Approach

Selecting the appropriate simulation model is crucial for accurately predicting the impact of new technologies. A poorly chosen model can lead to inaccurate or misleading results, hindering effective decision-making. Understanding the nature of the system being simulated, the specific questions being asked, and the available data are all critical factors in determining the most suitable simulation approach. Carefully considering these factors will significantly enhance the reliability and usefulness of the simulation outcomes.

Different simulation approaches, like agent-based modeling, system dynamics, or Monte Carlo methods, have varying strengths and weaknesses. Understanding these nuances is paramount to selecting a model that aligns with the complexity of the technological innovation and the desired level of detail in the analysis.

Considering System Complexity

The complexity of the system being simulated is a primary determinant in model selection. A simple, linear system might be adequately modeled using a basic statistical approach, while a complex, interconnected system, like a supply chain incorporating a new automated manufacturing process, might require a more sophisticated agent-based model. The level of interaction and feedback loops within the system must be carefully considered when making the selection.

Furthermore, the interdependencies between different components of the system need to be addressed within the model. A well-chosen model will accurately represent these interdependencies, providing a more realistic representation of the system's behavior.

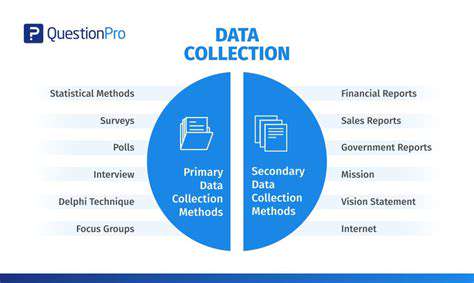

Data Availability and Quality

The availability and quality of data are essential factors in selecting an appropriate simulation model. A complex model requiring extensive data sets might be inappropriate if sufficient data are unavailable or unreliable. A less complex model may suffice if data limitations exist, but it's crucial to be transparent about these limitations when interpreting the results.

Data preprocessing and validation steps are critical to ensure the accuracy and reliability of the simulation. Inaccurate or incomplete data can lead to inaccurate simulation results, potentially impacting the decision-making process concerning the adoption of new technologies.

Defining the Scope of the Simulation

Clearly defining the scope of the simulation is paramount to selecting the right model. What aspects of the new technology's impact are being investigated? What time horizon is being considered? These questions will influence the degree of detail needed in the model. A simulation focused on short-term operational impacts might require a simpler model than one investigating long-term societal effects.

Calibration and Validation Procedures

Rigorous calibration and validation procedures are essential for ensuring the reliability of the chosen simulation model. Calibration involves adjusting model parameters to match historical data, while validation assesses the model's ability to accurately reproduce known outcomes. The quality of the calibration and validation processes will directly impact the confidence that can be placed in the simulation's predictions concerning the impact of the new technology.

Thorough testing and validation against real-world data are crucial to ensure that the model accurately represents the system under consideration. This process helps identify potential biases and errors in the model's structure or parameters.

Evaluating Model Assumptions

It is essential to critically evaluate the assumptions underlying the chosen simulation model. Assumptions about system behavior, user interactions, or external factors can significantly influence the simulation's outcomes. Recognizing and clearly articulating these assumptions is crucial for transparency and understanding the limitations of the model's predictions.

Recognizing and acknowledging potential limitations in the model is critical. These limitations can stem from simplified representations of reality, data constraints, or the inherent uncertainties associated with future projections. By clearly understanding these limitations, decision-makers can make more informed choices based on the simulation results.

Considering Computational Resources

The computational resources required to run the simulation should be considered. Complex models may require significant processing power and memory, potentially impacting the feasibility of conducting the analysis. The choice of simulation software and hardware should be carefully evaluated to ensure that the model can be executed efficiently.

The processing time and storage space required for running the simulation should be carefully assessed to determine its practical viability. This consideration is essential to avoid delays or limitations in the analysis process, ensuring that the simulation can deliver timely and relevant outcomes.

Read more about Simulating the Impact of New Technologies on Supply Chain Performance

Hot Recommendations

- Beyond Buzzwords: Real World Applications of Supply Chain Tech

- Digital twin for simulating human robot collaboration scenarios

- The Future of Supply Chain Strategy Development: AI Driven

- Big Data in Supply Chain: Challenges and Opportunities

- Generative AI for Supply Chain Workforce Augmentation

- Simulating the Impact of Supplier Disruptions with Digital Twins

- Sustainable urban logistics planning and policy

- Overcoming Data Fragmentation in Global and Multi Enterprise Supply Chains

- Robotics for cross docking operations: Speeding transit

- Natural language generation for automated weekly supply chain reports