Computer vision for detecting stockouts

Stockouts, the frustrating absence of a product from a retailer's shelves, are a pervasive issue in the retail industry. They can lead to significant financial losses and erode customer satisfaction, impacting both the short-term sales and the long-term brand reputation. Understanding the root causes and implementing effective solutions is crucial for retailers aiming to optimize their inventory management.

Many retailers underestimate the impact of stockouts on their bottom line. The lost sales from unavailable products can quickly add up, and the cost of lost customer goodwill can be even more substantial in the long run. Retailers need to develop proactive strategies to prevent stockouts and mitigate their negative consequences.

Demand Forecasting Challenges

Accurate demand forecasting is a critical component of effective inventory management. Retailers often struggle to anticipate fluctuations in consumer demand, leading to either overstocking of certain items or, more commonly, stockouts of popular products. External factors such as seasonal changes, economic downturns, and even unexpected events can significantly impact demand, making precise forecasting a significant challenge.

Poor forecasting can lead to significant financial losses. Overstocking ties up capital in unsold inventory, while stockouts result in lost sales and frustrated customers. Finding a balance between these extremes is vital for a healthy retail business.

Supply Chain Disruptions

The modern retail supply chain is complex and interconnected, often spanning multiple countries and continents. Disruptions, such as natural disasters, political instability, transportation issues, and even labor shortages, can disrupt the flow of goods, leading to delays and stockouts. These disruptions can be unpredictable and difficult to anticipate, requiring retailers to develop robust contingency plans.

Supply chain issues can be particularly devastating for retailers who rely on just-in-time inventory systems. These systems, while efficient in normal times, become highly vulnerable to disruptions. This highlights the need for redundancy and resilience in modern supply chain management.

Inventory Management Systems

Outdated or inefficient inventory management systems can contribute significantly to stockouts. Lack of real-time data visibility, inaccurate data entry, and slow response times to changing demand can result in poor inventory control. Retailers need to invest in advanced inventory management systems that provide real-time insights into stock levels, sales trends, and order fulfillment.

Effective inventory management systems are crucial for mitigating stockouts. These systems provide the essential data and insights to make informed decisions about ordering, stocking, and fulfilling customer orders. Integrating these systems with other aspects of the business, such as sales and marketing, is also vital.

Insufficient Safety Stock Levels

Safety stock is the extra inventory held to buffer against unexpected fluctuations in demand or supply chain disruptions. Insufficient safety stock levels can easily lead to stockouts, especially during periods of high demand or unexpected events. Calculating appropriate safety stock levels requires careful analysis of historical data, predicted demand variability, and potential supply chain risks.

Retailers often fail to adequately assess the need for safety stock. This oversight can have a devastating impact on their ability to meet customer demand and avoid stockouts. This is a vital aspect of mitigating risk and maintaining a consistently successful business.

Poor Customer Communication

Effective communication with customers is vital when a product is out of stock. Clear and timely communication about product availability, estimated restocking times, and alternative options can help mitigate customer frustration and maintain loyalty. Poor communication can quickly escalate customer dissatisfaction and damage brand perception.

Transparent communication regarding stockouts is crucial for maintaining customer trust. Offering alternatives, such as backorders or similar products, can demonstrate a commitment to customer satisfaction and help manage negative perceptions.

How Computer Vision Systems Work

Understanding the Core Components

Computer vision systems, at their heart, are sophisticated algorithms that process visual information from cameras or other image sensors. This involves a complex interplay of image acquisition, pre-processing, feature extraction, and object recognition. The initial stage captures the image data, which is then cleaned and prepared for analysis. This pre-processing often includes tasks like noise reduction, contrast enhancement, and color correction. Crucially, the system identifies key features within the image, like edges, textures, or shapes, to differentiate between different objects. These features are then used as input for classification or detection algorithms, which ultimately determine what's present in the image.

A crucial aspect of these systems is their ability to learn. Through extensive training on labeled datasets, the algorithms progressively improve their accuracy in recognizing specific objects or patterns. Imagine training a system to identify empty shelves. The training data might consist of thousands of images, some showing fully stocked shelves, others with empty spaces. By analyzing these images and their corresponding labels, the system learns to distinguish between the two scenarios. This learning process allows the system to adapt to variations in lighting, camera angles, and product appearances, making it more robust in real-world applications.

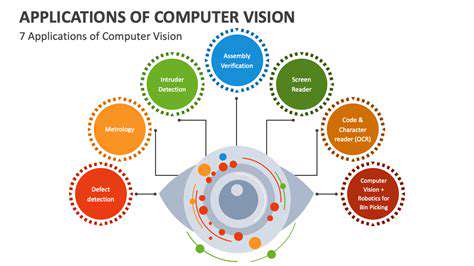

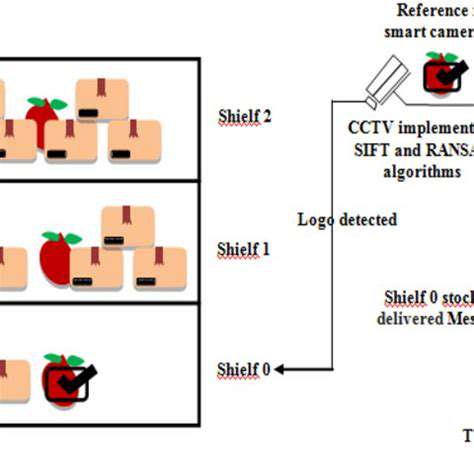

Applying Computer Vision to Stockout Detection

In the context of detecting stockouts, computer vision systems can be deployed in various ways. One common approach involves using cameras to monitor shelves in a retail environment. The system analyzes images of these shelves, identifying the presence or absence of specific products. This real-time monitoring allows for rapid detection of empty spaces, providing valuable insights into inventory levels. The system can also be programmed to recognize subtle indicators of low stock, like a significantly reduced number of items on a shelf or the absence of a particular product from its designated location.

Beyond simple presence/absence, sophisticated computer vision systems can also analyze the arrangement and spacing of products. This allows for a more granular understanding of inventory. For instance, it can differentiate between a completely empty shelf and a shelf with items that are simply out of alignment. This level of detail is crucial for accurately quantifying the extent of stockouts and potentially identifying trends or patterns that may be affecting inventory levels. This nuanced understanding is far more effective than relying on simple visual inspection or manual stock taking.

Furthermore, computer vision can be integrated with other systems, such as point-of-sale (POS) data or sales forecasting models. By combining these data sources, a more complete picture of the current and projected demand can be established. This can enhance the accuracy of stockout predictions and enable proactive replenishment strategies. The ability to combine data sources adds a significant layer of intelligence to the stockout detection process, allowing retailers to anticipate and address issues before they lead to lost sales or customer dissatisfaction.

Beyond Simple Counting: Advanced Applications of Computer Vision

Advanced Approaches to Analyzing Data

Moving beyond rudimentary counting, advanced data analysis techniques offer a deeper understanding of trends, patterns, and relationships within datasets. These methods often involve statistical modeling, machine learning algorithms, and sophisticated visualization tools. Employing these approaches allows for the identification of more nuanced insights and the development of more accurate predictions, ultimately leading to better decision-making based on data-driven evidence.

The key to success in advanced analysis lies in understanding the specific questions being asked. By carefully formulating the research questions and selecting the appropriate analytical methods, researchers can uncover meaningful patterns and relationships within the data. This approach is particularly crucial when dealing with complex datasets that contain numerous variables and potential confounding factors.

Statistical Modeling for Deeper Insights

Statistical modeling is a powerful technique for exploring relationships between variables and making predictions. By fitting mathematical models to data, researchers can quantify the strength and direction of these relationships. This approach allows for a deeper understanding of the underlying mechanisms driving observed patterns.

Different types of statistical models exist, such as linear regression, logistic regression, and time series analysis, each with unique strengths and weaknesses. The choice of model depends on the nature of the data and the specific research questions being addressed. Choosing the correct model is vital for deriving accurate and reliable results from complex data sets.

Machine Learning for Predictive Capabilities

Machine learning algorithms are increasingly used to analyze complex datasets and make predictions about future outcomes. These algorithms learn from historical data and identify patterns that might be missed by traditional statistical methods. Furthermore, these algorithms can be applied to a wide range of problems, from customer churn prediction to fraud detection.

Machine learning models, such as support vector machines, neural networks, and decision trees, can be trained on large datasets to identify complex relationships and make accurate predictions. Machine learning holds the potential to revolutionize various fields by automating complex tasks and improving efficiency. This technology has the potential to revolutionize various fields.

Data Visualization for Enhanced Understanding

Data visualization plays a crucial role in communicating insights derived from advanced analyses. By transforming complex data into visual representations, such as charts, graphs, and maps, researchers can easily identify patterns, trends, and anomalies. This visual approach often makes it easier to identify relationships and draw conclusions, even for individuals without extensive statistical expertise.

Effective data visualizations are crucial for communicating findings clearly and concisely. Visualizations should be carefully designed to accurately represent the data and highlight key insights. Clear and compelling visualizations can transform raw data into actionable knowledge, enabling stakeholders to understand and act upon the findings in a meaningful way.

Beyond the Numbers: Contextual Understanding

While advanced analytical techniques are essential, it is equally important to consider the context in which the data was collected and the potential biases that might be present. Understanding the limitations of the data and the potential biases present is crucial for interpreting the results accurately. This contextual understanding helps ensure that the conclusions drawn are both valid and meaningful.

Furthermore, the results of any analysis should be interpreted in light of existing knowledge and theories. Integrating the results with existing frameworks is important to ensure that the findings are consistent with established knowledge and that new insights are appropriately contextualized. By doing so, we can avoid drawing conclusions that are unsupported by evidence or that contradict established understanding.

The Benefits of Automated Stockout Detection

Minimizing Lost Revenue

Automated stockout prevention systems are crucial for maximizing revenue. By proactively identifying and addressing potential stockouts, businesses can avoid the significant financial losses associated with unmet customer demand. This proactive approach translates to more consistent sales and a more predictable income stream, allowing businesses to better forecast and manage their financial resources.

Predictive analytics embedded within automated stockout solutions can forecast future demand, enabling businesses to maintain optimal inventory levels. This minimizes the risk of running out of popular items, which can lead to lost sales and customer dissatisfaction, resulting in a negative impact on the company's bottom line.

Improved Customer Satisfaction

Customers appreciate consistency and reliability. Automated stockout systems help businesses maintain consistent availability of in-demand products. This predictability fosters customer loyalty and positive brand perception. Consistent availability builds trust and confidence, leading to repeat business and positive word-of-mouth referrals.

Enhanced Operational Efficiency

Manual stock management can be time-consuming and prone to errors. Automated systems streamline the inventory tracking process, freeing up valuable staff time for more strategic tasks. This increased efficiency translates to a more streamlined workflow and improved overall operational performance.

Reduced Waste and Spoilage

For perishable goods, automated stockout systems help avoid the waste and spoilage associated with overstocking or understocking. By optimizing inventory levels, businesses can minimize the loss of perishable items, saving money and reducing their environmental footprint. This meticulous control ensures a balance between customer demand and product preservation.

Optimized Inventory Management

Automated systems facilitate real-time tracking of inventory levels across various locations. This allows businesses to quickly identify stock discrepancies and take corrective action to avoid stockouts. This streamlined approach provides a more efficient and accurate view of inventory, leading to better decision-making and improved stock control.

Increased Accuracy and Reduced Errors

Manual stock management is susceptible to human error. Automated systems significantly reduce the risk of errors in inventory tracking and forecasting. This improved accuracy allows businesses to make more informed decisions regarding purchasing, production, and supply chain management. The reduction in errors minimizes costly mistakes and contributes to a more reliable and efficient operation.

Streamlined Supply Chain Management

Automated stockout systems can improve communication and collaboration throughout the supply chain. Improved visibility into inventory levels allows for better coordination with suppliers, distributors, and retailers. This seamless integration reduces delays and disruptions, enhancing the overall efficiency and resilience of the supply chain. This leads to a more responsive and adaptable supply chain, capable of quickly adapting to changing market demands.