The Rise of Robotics in Supply Chain Automation

The use of robots is extending beyond traditional manufacturing settings. Service industries are exploring the potential of robots for tasks like customer service, delivery, and healthcare. Robots are being developed for tasks like greeting customers, taking orders, and even assisting with medical procedures. This expansion into new sectors signifies a broader adoption of robotics in everyday life.

The Future of Robotics: Artificial Intelligence Integration

The future of robotics is closely intertwined with advancements in artificial intelligence (AI). AI is empowering robots with greater cognitive abilities, allowing them to learn, adapt, and make decisions in complex environments. This integration of AI and robotics will lead to even more sophisticated and versatile robots, opening up new possibilities for automation. The future holds the promise of robots working collaboratively with humans in ways we cannot yet imagine.

Beyond Warehousing: Robotics in Transportation and Distribution

Autonomous Vehicle Integration

The integration of autonomous vehicles (AVs) into transportation and distribution networks is a rapidly evolving field, promising significant improvements in efficiency and cost-effectiveness. Autonomous trucks, delivery robots, and even self-driving cargo ships are being explored and deployed in various settings. These vehicles, often equipped with advanced sensors and AI algorithms, can navigate complex routes, optimize delivery schedules, and reduce the need for human intervention, particularly in tasks like long-haul trucking and last-mile delivery.

One key benefit of AV integration lies in the potential for 24/7 operation, minimizing downtime and accelerating delivery times. Further, the ability to process and analyze vast amounts of real-time data from various sources, including traffic patterns and weather conditions, enables AVs to adapt to changing circumstances and make optimal decisions in real-time. This level of adaptability and responsiveness contributes to a more reliable and efficient supply chain.

Robotic Handling and Sorting

Robotics are increasingly taking on critical roles within warehouses and distribution centers, moving beyond simple picking and packing to encompass more complex tasks. Advanced robotic arms, equipped with sophisticated vision systems, can handle various types of goods with precision and speed, significantly increasing the efficiency of sorting and packaging operations. This automation eliminates the risks associated with repetitive manual handling, reducing worker injury and improving overall safety.

Furthermore, robotic systems are capable of handling a diverse range of products, from small packages to heavy machinery. This versatility allows for a more efficient use of space and resources within distribution centers, minimizing bottlenecks and optimizing overall throughput. Robotic sorting systems, utilizing sophisticated algorithms and image recognition, can quickly and accurately categorize and direct items to their designated destinations, streamlining the entire distribution process.

The implementation of these robotic systems not only enhances operational efficiency but also leads to improved inventory management, reducing the potential for errors and allowing for real-time tracking of goods throughout the entire supply chain. This, in turn, results in greater transparency and accountability, enhancing customer satisfaction.

Beyond improving speed and accuracy, robotic handling and sorting also contribute to cost reduction by minimizing labor costs and maximizing the utilization of warehouse space.

These automated systems can work tirelessly, even in harsh or demanding environments, further increasing the overall productivity and reliability of the entire distribution network.

The ongoing advancement of robotic technology in this area promises even greater levels of automation and optimization in the future.

The Benefits of Robotic Integration: Enhanced Accuracy, Speed, and Safety

Streamlined Processes and Enhanced Efficiency

Robotic integration, when implemented correctly, dramatically improves operational efficiency by automating repetitive tasks. This leads to a significant reduction in manual errors, allowing employees to focus on more complex and strategic work. By automating mundane processes, businesses can free up valuable time and resources, resulting in faster turnaround times and increased productivity. This optimized workflow translates directly into a more streamlined and efficient operation, ultimately boosting overall profitability.

Furthermore, Robotic integration often leads to improved accuracy and consistency in tasks. The precision and reliability of robots minimize the risk of human error, ensuring that work is performed to the highest standards every time. This consistent quality control is crucial for maintaining customer satisfaction and upholding brand reputation.

Reduced Labor Costs and Increased Scalability

One of the most compelling benefits of robotic integration is the potential for reduced labor costs. While initial investment in robotic systems can be substantial, the long-term savings from reduced labor expenses, fewer errors, and increased productivity can be substantial. This reduced reliance on human labor allows businesses to scale operations more efficiently and effectively, particularly in industries facing labor shortages or rising labor costs.

Robotic systems can also be easily reprogrammed and adjusted to handle different tasks, offering increased scalability for businesses. Adapting to changing market demands or production needs becomes more flexible and faster with robotic systems in place. This adaptability is critical for businesses seeking to remain competitive and responsive in dynamic environments.

Improved Safety and Working Conditions

In many industries, certain tasks are inherently dangerous or physically demanding for human workers. Robotic integration can significantly improve safety by automating these hazardous jobs. This shift reduces the risk of workplace accidents and injuries, protecting employees and fostering a safer working environment. Robots can also handle tasks in harsh or dangerous conditions, including environments that are too hot, cold, or dirty for human workers.

By automating dangerous tasks, robotic integration can also lead to improved working conditions for human employees. This allows employees to focus on higher-level responsibilities, resulting in enhanced job satisfaction and reduced employee burnout.

Enhanced Data Collection and Analysis

Robotic integration often provides the ability to collect and analyze data more efficiently and effectively. These systems can gather data from various sources and processes, generating comprehensive insights that can be used for decision-making. This data-driven approach can help businesses understand their operations better, identify areas for improvement, and make more informed strategic decisions.

Data collected by robotic systems can also be analyzed to identify trends and patterns. This allows businesses to anticipate future needs and make proactive adjustments to operations, leading to greater agility and responsiveness in the marketplace. This improved data analysis provides a competitive edge, enabling businesses to make better use of available resources and optimize their performance.

Addressing Challenges and Considerations in Robotic Integration

Optimizing Workflow for Seamless Integration

Robotic integration into existing workflows demands careful planning and execution to avoid disruptions and maximize efficiency. A crucial step involves analyzing current processes to identify areas where robots can augment human capabilities, potentially increasing output and reducing errors. This analysis should consider not only the tasks robots can perform but also the necessary adjustments to human roles, ensuring a smooth transition and minimizing retraining needs. Furthermore, establishing clear communication channels between human operators and robotic systems is paramount for efficient coordination and problem-solving during the integration process.

Detailed documentation of the integration process, including pre-integration planning, implementation steps, and post-integration adjustments, is essential for future troubleshooting and scalability. This comprehensive documentation also serves as a valuable training resource for personnel involved in the robotic system's operation and maintenance. Furthermore, proactive monitoring of the system's performance is crucial to identify and address potential issues early on and maintain optimal operational efficiency.

Safety Protocols and Risk Mitigation

Prioritizing safety is paramount in any robotic integration project. Implementing robust safety protocols, including physical barriers, emergency shut-off mechanisms, and clear safety zones, is critical to preventing accidents and ensuring the well-being of human operators working alongside robotic systems. Regular safety inspections and maintenance of robotic equipment are essential to maintaining operational safety standards and preventing potential hazards. Comprehensive training programs for personnel involved in operating and maintaining the robotic systems are crucial to ensure they understand and adhere to safety procedures.

Careful consideration of potential risks associated with robotic integration is essential. This includes assessing the possibility of equipment malfunctions, human errors, and unforeseen circumstances. Developing contingency plans and emergency procedures to address these risks is vital to minimizing the impact of any potential incidents. Regular risk assessments and updates to safety protocols should be conducted to address evolving risks and maintain a proactive approach to safety.

Addressing Cost Considerations and ROI

The financial implications of robotic integration should be carefully evaluated to ensure the project aligns with the organization's budget and expected return on investment (ROI). This involves assessing the initial costs of purchasing or leasing the robotic systems, including installation and setup expenses. Furthermore, ongoing operational costs, such as maintenance, repairs, and potential energy consumption, should be considered to accurately predict long-term financial commitments. A comprehensive ROI analysis, considering factors such as increased productivity, reduced labor costs, and improved product quality, is essential to justify the investment and demonstrate its long-term value.

Understanding the long-term financial implications of the robotic integration is critical to successful implementation. This includes anticipating potential upgrades and replacements of robotic systems over time. Strategic planning for future technology developments and their potential impact on the existing robotic infrastructure is also crucial to ensure the investment remains relevant and cost-effective in the long run. Thorough cost-benefit analysis is essential to ensure the financial viability of the integration project and to maximize the return on investment for the organization.

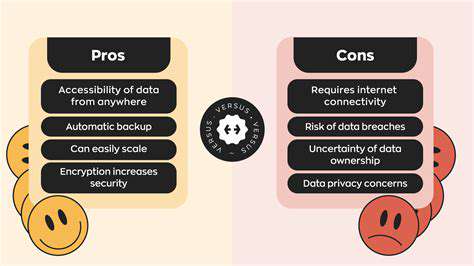

Technological Compatibility and Future Scalability

Ensuring compatibility between the new robotic systems and existing infrastructure is vital for a smooth integration process. This includes compatibility with existing software systems, network connectivity, and physical workspace layouts. Careful planning for potential future expansions and technological advancements is crucial to avoid future compatibility issues. Considering the potential for upgrades and advancements in robotic technology is essential for maintaining long-term operational efficiency and avoiding obsolescence. Integrating scalability into the planning phase ensures the system can adapt to changing needs and future growth.

Proactive planning for future technological advancements is crucial for long-term sustainability. This includes investigating and evaluating emerging technologies to ensure compatibility and maintain competitiveness. Anticipating future needs and ensuring the robotic systems can adapt to evolving technological landscapes is key to ensuring long-term operational success. This also includes researching and implementing standards that promote interoperability between various robotic systems and platforms, enabling future integration with other technologies and systems.

The Future of Robotics in Supply Chain Management

The Rise of Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human workers in shared workspaces. This collaborative approach is revolutionizing supply chain operations, enabling increased productivity and efficiency. Cobots are particularly adept at repetitive tasks, freeing up human employees for more complex and strategic roles. This shift in the division of labor is a key trend in the future of robotics, allowing for a more human-centered approach to automation.

Cobots are increasingly equipped with advanced sensors and AI, enabling them to adapt to dynamic environments and handle varied tasks with greater precision and accuracy. This adaptability is crucial for the complexities of modern supply chains, which often involve fluctuating demands and changing product lines.

Autonomous Guided Vehicles (AGVs)

Autonomous Guided Vehicles (AGVs) are transforming material handling within warehouses and distribution centers. By navigating predetermined paths, AGVs can efficiently transport goods from one location to another, significantly reducing manual handling and improving operational speed. The integration of AGVs with other robotic systems is creating sophisticated automated systems capable of managing entire supply chain processes.

The use of AGVs is particularly impactful in large-scale operations, streamlining the movement of materials and improving overall warehouse efficiency. This automation reduces labor costs and minimizes errors associated with manual handling.

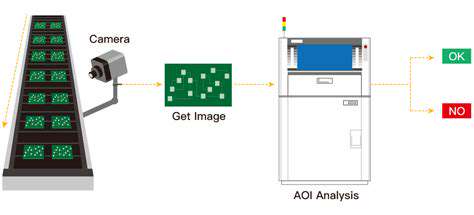

Advanced Vision Systems

Advanced vision systems are becoming increasingly sophisticated, enabling robots to identify, locate, and manipulate objects with greater accuracy. These systems are crucial for tasks such as picking and packing, quality control, and inventory management. The integration of vision systems with other robotic technologies leads to more intelligent and adaptable robotic systems.

Vision systems allow robots to work in diverse and unstructured environments, increasing flexibility and reducing the need for highly structured workspaces. This is a game-changer for supply chain logistics, leading to greater efficiency in handling diverse product types and sizes.

AI-Powered Predictive Maintenance

Predictive maintenance is a significant advancement in robotics, allowing robots and automated systems to anticipate equipment failures before they occur. This proactive approach can drastically reduce downtime and improve the reliability of supply chain operations. This predictive capability is vital for maintaining optimal performance and minimizing disruptions.

By analyzing data from various sensors, robots can identify patterns and predict potential equipment issues. This data-driven approach allows for proactive maintenance schedules, reducing operational costs and minimizing unexpected delays.

3D Printing and Customized Manufacturing

The integration of 3D printing into supply chains is enabling on-demand manufacturing and customization. This allows for rapid prototyping, personalized products, and reduced lead times. This flexibility is a revolutionary concept for supply chains, enabling faster response to fluctuating demands and customer preferences.

Furthermore, 3D printing can facilitate decentralized production, reducing reliance on centralized facilities and improving response times to local market demands. This decentralized approach can improve efficiency and reduce transportation costs.

Robotics in Last-Mile Delivery

The increasing use of robots in last-mile delivery is transforming the delivery process. Autonomous delivery robots are being deployed in urban areas to transport packages to consumers, potentially revolutionizing the way goods are delivered. This automation is expected to significantly reduce delivery times and improve efficiency in the final stage of the supply chain.

These robots can navigate complex urban environments, including sidewalks and crowded streets, efficiently and safely delivering packages to their destinations. This development promises to be transformative for the final leg of the supply chain, improving convenience and speed for consumers.

Ethical Considerations and Workforce Adaptability

The increasing automation of supply chains raises ethical concerns regarding job displacement and the need for workforce retraining. Addressing these concerns proactively is vital for ensuring a smooth transition to a future dominated by robotics.

It is imperative to focus on retraining and upskilling programs to equip the workforce with the necessary skills to succeed in the evolving job market. This will help ensure a smooth and equitable transition to a future shaped by sophisticated robots and automated systems.