The Rise of Autonomous Forklifts for Internal Logistics

Overcoming Challenges in Autonomous Forklift Implementation

Initial Investment and ROI

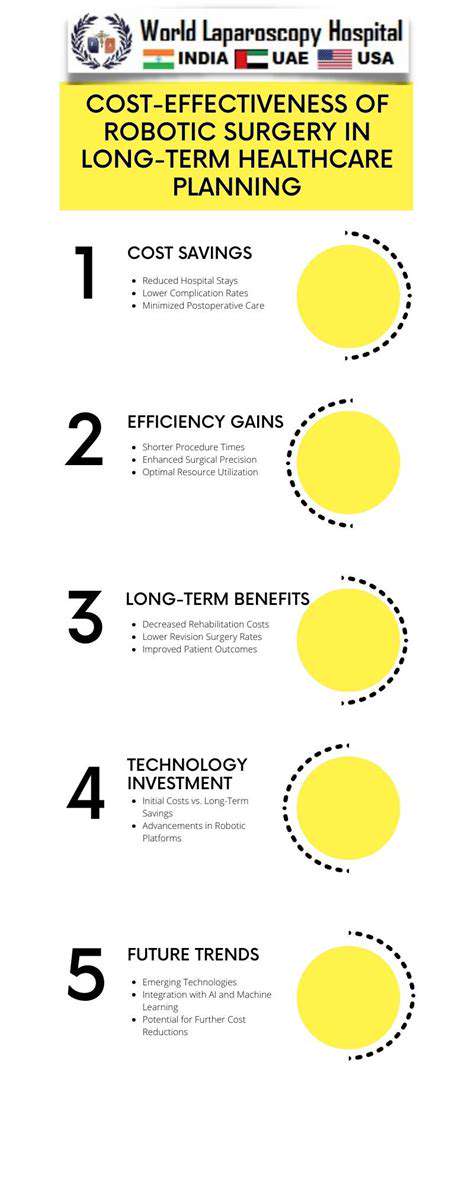

Implementing autonomous forklifts involves a significant upfront investment, encompassing the purchase price of the robots themselves, specialized charging infrastructure, and potential upgrades to existing warehouse layouts. Calculating the return on investment (ROI) requires careful consideration of factors like reduced labor costs, increased operational efficiency, and potential savings from minimized downtime. A thorough cost-benefit analysis is crucial to justify the initial outlay and demonstrate the long-term profitability of the autonomous fleet.

While the initial investment might seem substantial, the potential for long-term savings and increased productivity often outweighs the initial outlay. Careful planning, realistic projections, and a clear understanding of the operational benefits are essential to achieving a positive ROI and demonstrating the value proposition of autonomous forklift technology.

Integration with Existing Infrastructure

Integrating autonomous forklifts into an existing warehouse environment requires careful planning and consideration of the current infrastructure. Navigational systems need to be compatible with the layout of the warehouse, including any existing obstacles or safety protocols. This might necessitate modifications to the warehouse layout, installing sensors, or updating existing safety measures to ensure a smooth transition and prevent any operational disruptions.

Careful planning and thorough assessments of the existing infrastructure are crucial to ensure a seamless transition. A phased approach to implementation, allowing for adjustments and monitoring, is often recommended to minimize disruptions and maximize the effectiveness of the autonomous forklift system.

Training and Personnel Development

Transitioning to autonomous forklifts requires retraining and upskilling existing warehouse personnel. Workers need to be educated on the new technologies, safety protocols specific to autonomous vehicles, and their roles in maintaining and monitoring the automated systems. This training should encompass both theoretical understanding and practical application to ensure a smooth transition and optimal utilization of the new technology.

The training process should be comprehensive and tailored to the specific needs of the workforce, covering everything from basic operation to advanced troubleshooting. This investment in personnel development is crucial for ensuring a smooth transition and maximizing the benefits of the new technology.

Safety Protocols and Compliance

Implementing stringent safety protocols is paramount when introducing autonomous forklifts into the workplace. These protocols must address potential hazards, incorporate fail-safes, and comply with all relevant industry regulations. Safety should be a primary concern throughout the entire implementation process, from initial planning to ongoing operation.

Regular safety audits and evaluations are essential to identify potential hazards and ensure compliance with safety regulations. Continuous improvement and adaptation of safety protocols based on real-world data and feedback are critical for maintaining a safe and productive work environment.

Maintenance and Support

Autonomous forklifts require specific maintenance procedures and support systems to ensure optimal performance and longevity. This includes regular inspections, software updates, and potential repairs. Establishing a robust maintenance schedule and securing reliable support services are crucial for minimizing downtime and maximizing the efficiency of the autonomous fleet.

Scalability and Future Expansion

The implementation of autonomous forklifts should be designed with scalability and future expansion in mind. The system should be adaptable to accommodate future growth and expansion of the warehouse operations. This includes considerations for future technological advancements and potential modifications to the warehouse layout.

A flexible and adaptable system will allow for future expansion and growth. Planning for potential upgrades and modifications to the system will ensure that the autonomous forklift fleet remains efficient and effective as the business evolves.

Operational Efficiency and Productivity

Autonomous forklifts can significantly improve operational efficiency and productivity in warehouses. By automating tasks, these vehicles can reduce labor costs, increase throughput, and minimize downtime. This increased efficiency can lead to significant cost savings and improved profitability.

Optimizing the autonomous forklift system for specific warehouse tasks and workflows can further enhance efficiency. Regular monitoring and analysis of operational data can provide insights for further improvements and enhancements to the system, leading to increased productivity and reduced operational costs.

The Future of Internal Logistics with Autonomous Forklifts

Optimizing Warehouse Operations

The future of internal logistics hinges significantly on the optimization of warehouse operations. This involves leveraging automation and technology to streamline processes, reduce errors, and improve efficiency. Implementing advanced warehouse management systems (WMS) with real-time tracking and inventory management capabilities is crucial for maintaining order and minimizing delays. This approach will also enhance productivity and enable better forecasting of resource allocation, such as labor and equipment.

Furthermore, the integration of robotics and automated guided vehicles (AGVs) into warehouse layouts can drastically reduce manual labor and increase the speed of order fulfillment. These automated systems can operate 24/7 with precision and consistency, ensuring timely and accurate delivery of goods.

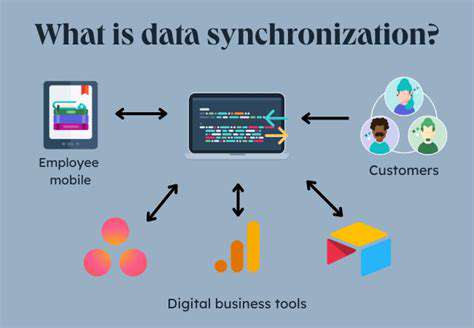

Embracing Data-Driven Decision Making

Internal logistics professionals are increasingly relying on data analytics to gain a deeper understanding of their operations. By collecting and analyzing data related to inventory levels, order fulfillment times, and transportation costs, businesses can identify bottlenecks, optimize routes, and make more informed decisions. This data-driven approach can help organizations anticipate future demands and adjust resources accordingly.

Data analysis can reveal hidden trends and patterns that would otherwise remain unnoticed. This allows for proactive adjustments to processes, leading to significant cost savings and improved overall performance. Predictive analytics can also be integrated into the logistics strategy to anticipate potential issues and implement preventative measures.

The Role of Technology in Enhancing Efficiency

Technology plays a pivotal role in shaping the future of internal logistics. From sophisticated warehouse management systems to advanced inventory tracking, and from automated guided vehicles to real-time visibility tools, technology provides a powerful set of tools to boost efficiency and accuracy. The integration of these tools can significantly improve order fulfillment times and reduce labor costs.

Sustainable Practices and Green Logistics

The future of internal logistics is inextricably linked to sustainable practices. Businesses are increasingly recognizing the importance of minimizing their environmental impact through green logistics initiatives. This includes optimizing transportation routes to reduce fuel consumption, utilizing eco-friendly packaging materials, and exploring alternative transportation methods like electric vehicles. Adopting sustainable practices not only protects the environment but also enhances a company's brand image and potentially reduces operational costs in the long run.

Implementing sustainable strategies can lead to a significant reduction in carbon emissions and a positive impact on the environment. By embracing eco-friendly solutions, companies can demonstrate their commitment to sustainability and attract environmentally conscious customers.

Read more about The Rise of Autonomous Forklifts for Internal Logistics

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit