The Rise of AI Powered Control Towers for Supply Chains

The Future of Supply Chain Management

AI-Driven Visibility and Control

The integration of Artificial Intelligence (AI) into supply chain management is revolutionizing how businesses operate. AI-powered control towers offer unprecedented visibility into every stage of the supply chain, from raw materials sourcing to final product delivery. This granular visibility allows for real-time tracking and analysis of data, enabling proactive adjustments to optimize processes and mitigate potential disruptions. By identifying bottlenecks and inefficiencies in real-time, companies can make informed decisions to improve efficiency and reduce costs, leading to a significant competitive advantage.

This heightened visibility extends beyond traditional metrics. AI algorithms can analyze vast datasets to identify subtle patterns and anomalies, predicting potential problems before they escalate. For example, an algorithm might detect a slight delay in a supplier's delivery, which, if left unaddressed, could trigger a domino effect throughout the entire supply chain. By anticipating these disruptions, companies can implement preventative measures, ensuring smooth operations and minimizing potential financial losses.

Predictive Analytics for Proactive Decision Making

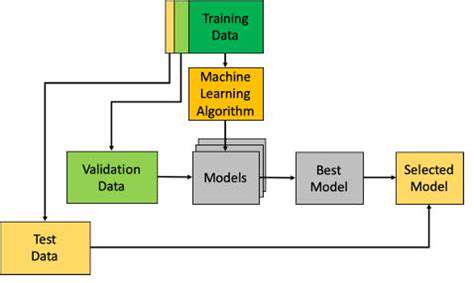

AI algorithms are not just reactive; they are predictive. By analyzing historical data, current trends, and external factors, AI-powered control towers can forecast future demand, optimize inventory levels, and anticipate potential disruptions. This proactive approach allows businesses to adjust their strategies in advance, minimizing the impact of unexpected events and ensuring a more resilient supply chain.

Predictive analytics allows businesses to make data-driven decisions regarding inventory management, resource allocation, and transportation logistics. For instance, by predicting future demand fluctuations, companies can adjust production schedules and optimize warehouse inventory, minimizing storage costs and preventing stockouts or overstocking. This predictive capability also extends to identifying potential risks, such as geopolitical instability or natural disasters, allowing companies to implement contingency plans well in advance.

Enhanced Collaboration and Communication

AI-powered control towers facilitate seamless communication and collaboration among all stakeholders involved in the supply chain. Real-time data sharing and automated alerts ensure that everyone involved has access to the most up-to-date information, enabling faster response times to issues and improved coordination. This collaborative environment fosters a more efficient and agile supply chain, enabling quicker problem resolution and reducing delays.

Furthermore, AI can translate data into actionable insights for various stakeholders, including suppliers, logistics providers, and customers. This transparency and shared understanding significantly enhance collaboration, promoting trust and efficiency throughout the entire supply chain network. The ability to communicate effectively and quickly with all partners is crucial for minimizing disruptions and ensuring timely delivery.

Optimizing Resource Allocation and Efficiency

AI algorithms can optimize resource allocation across the entire supply chain, from production facilities and warehouses to transportation networks. By analyzing data on capacity, demand, and location, AI can identify the most efficient routes, optimize delivery schedules, and allocate resources effectively, maximizing output and minimizing waste. This dynamic optimization ensures that resources are used effectively, reducing costs and increasing overall efficiency.

This optimization extends to the allocation of personnel and equipment. AI can analyze the workload and skillsets of employees, dynamically assigning tasks to maximize productivity. Furthermore, AI can help optimize transportation routes, reducing fuel consumption and minimizing environmental impact, making the entire supply chain more sustainable. This ability to optimize resource allocation is critical for cost reduction and operational efficiency.

Read more about The Rise of AI Powered Control Towers for Supply Chains

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit