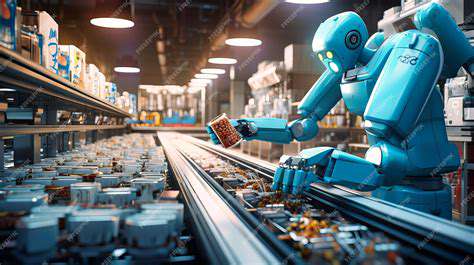

Robotics for automated handling of delicate products

Introduction to the Challenges of Automated Handling for Fragile Items

Defining Fragile Items

Fragile items, in the context of automated handling, are those susceptible to damage during transportation, manipulation, and storage. This encompasses a wide variety of goods, from delicate glassware and ceramics to electronic components and medical instruments. Their inherent vulnerability necessitates specialized handling protocols and technologies to ensure their safe and efficient movement within automated systems.

Identifying and categorizing these items based on specific fragility criteria is crucial for the design and implementation of effective automated handling solutions. Factors like material composition, dimensions, weight, and potential for breakage must be considered for appropriate protection measures.

Material Properties and Their Impact

The physical properties of fragile items directly influence the challenges of automated handling. For example, the inherent brittleness of glass necessitates careful consideration of the forces applied during gripping, lifting, and placement. Similarly, the flexibility of certain materials, while not inherently brittle, can still be susceptible to damage from excessive pressure or abrupt movements.

Understanding these material properties allows engineers to develop gripping mechanisms and handling strategies that minimize stress on the item and maintain its structural integrity throughout the automated process.

The Importance of Gentle Handling

Gentle handling is paramount in the automated handling of fragile items. Sudden movements, excessive pressure, or abrupt changes in direction can lead to catastrophic failure. Therefore, the design of robotic arms, grippers, and transport systems must prioritize controlled, slow motions and precise positioning to prevent damage.

Ensuring Consistent Force Application

Maintaining consistent force application throughout the entire handling process is critical. Varying pressures can lead to uneven stress distribution, causing fractures or deformities. Sophisticated sensors and actuators play a vital role in ensuring that the force applied to a fragile item remains within acceptable limits and avoids any localized stress points.

Addressing Environmental Factors

Environmental factors can significantly impact the handling of fragile items. Temperature fluctuations, humidity levels, and vibration can all contribute to increased risk of damage. Automated systems should be designed to mitigate these environmental effects, for example, by providing temperature-controlled environments or incorporating vibration dampening mechanisms to protect goods during transport.

Gripping Mechanisms and Their Effectiveness

The design of grippers is paramount for safe and efficient handling. Specialized grippers with soft padding, compliant surfaces, or vacuum-based systems are often necessary to avoid damage from direct contact. The choice of gripping mechanism is directly related to the material and shape of the item being handled.

Integration of Sensors and Feedback Systems

Sensors and feedback systems are essential for monitoring the interaction between the robotic system and the fragile item. Sensors can detect changes in force, position, and even subtle vibrations, allowing the system to adjust its handling strategy in real-time and prevent potential damage. This real-time feedback loop is crucial for ensuring the safety and integrity of the fragile items during automated handling.

Exploring the Types of Robotics for Delicate Item Handling

Types of Industrial Robots

Industrial robots are a diverse group, each designed for specific tasks within manufacturing environments. These robots are crucial for automating repetitive and often hazardous tasks, significantly boosting efficiency and minimizing human error. They range from simple, programmable robots that perform pick-and-place operations to complex articulated arms capable of intricate welding and assembly procedures. The choice of robot depends heavily on the specific demands of the production line, including the required precision, payload capacity, and workspace volume.

Different types of industrial robots include articulated robots, SCARA robots, and delta robots, each with unique characteristics. Articulated robots, with multiple joints, offer a high degree of flexibility and dexterity, making them suitable for a wide variety of tasks. SCARA robots, on the other hand, are better suited for tasks requiring high speed and precision in a planar workspace, such as packing and assembly lines. Delta robots are known for their speed and accuracy, particularly when dealing with small parts, a common feature in electronics manufacturing.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed specifically for shared workspaces with human operators. These robots are typically smaller and lighter than industrial robots, and their design prioritizes safety and ease of integration into existing workflows. Cobots are particularly valuable in settings where human dexterity and judgment are still required, but repetitive tasks can be offloaded to the robot.

Cobots often feature force-torque sensors and safety features like emergency stops and soft stops, which allow for safe interaction between humans and robots. This collaborative approach reduces the need for extensive safety cages and specialized environments often required for industrial robots, making them more accessible and cost-effective for smaller businesses and diverse applications.

Service Robots

Service robots are designed for tasks beyond manufacturing, encompassing a wide range of applications, from cleaning and security to healthcare and agriculture. These robots often feature advanced sensors, navigation systems, and artificial intelligence capabilities to perform their functions autonomously or semi-autonomously.

From vacuuming homes to assisting surgeons in the operating room, service robots are transforming various sectors. Specific examples include autonomous delivery robots for e-commerce, robotic vacuum cleaners for household chores, and surgical robots that provide precision and assistance during complex procedures. These robots are constantly evolving, with new advancements promising even more sophisticated and capable service robots in the future.

Mobile Robots

Mobile robots, often found in warehouse environments or logistics centers, are designed for navigation and transportation of materials. They often use sophisticated sensor systems and mapping software to navigate complex environments, moving goods from one location to another with minimal human intervention. These robots are crucial for automating and optimizing supply chain processes, resulting in greater efficiency and cost savings.

These robots vary in size and capabilities, from small, automated guided vehicles (AGVs) to larger autonomous mobile robots (AMRs) capable of handling heavier loads and more complex tasks. The use of mobile robots significantly impacts logistics, improving efficiency, and reducing the need for manual labor in material handling.

Applications and Future Trends in Robotic Delicate Product Handling

Applications of AI in Healthcare

Artificial intelligence (AI) is rapidly transforming the healthcare landscape, offering a wide range of applications. From assisting in diagnosis and treatment planning to improving patient outcomes and streamlining administrative tasks, AI is poised to revolutionize how we approach healthcare delivery. AI-powered tools can analyze medical images with greater accuracy and speed than human experts, potentially leading to earlier and more precise diagnoses of diseases like cancer and other conditions. Furthermore, AI algorithms can identify patterns in patient data to predict potential health risks and personalize treatment plans, ultimately improving patient outcomes.

AI-driven tools also play a crucial role in drug discovery and development. By analyzing vast datasets of biological information, AI algorithms can identify potential drug candidates and predict their efficacy and safety, significantly shortening the time and cost associated with bringing new drugs to market. This acceleration is critical for addressing unmet medical needs and improving global health.

AI in Customer Service

AI is increasingly used to enhance customer service experiences. Chatbots powered by natural language processing (NLP) are capable of handling a wide range of customer inquiries, providing instant support and resolving issues efficiently. This frees up human agents to focus on more complex or sensitive cases, ultimately improving customer satisfaction and reducing wait times. Furthermore, AI can analyze customer interactions to identify trends and preferences, enabling businesses to personalize service offerings and improve customer retention.

Beyond basic inquiries, AI can also be used to analyze customer feedback and identify areas for improvement in products and services. This data-driven approach allows businesses to tailor their offerings to better meet customer needs, creating a more satisfying and loyal customer base.

AI-Powered Education

AI is revolutionizing education by offering personalized learning experiences. Adaptive learning platforms utilize AI algorithms to tailor the learning process to individual student needs and learning styles, ensuring that each student receives the most effective and engaging instruction. This personalized approach can significantly improve student outcomes and make learning more accessible to diverse learners.

AI in Finance

The financial sector is embracing AI to enhance efficiency and reduce risk. AI algorithms are used to detect fraudulent transactions, assess credit risk, and automate investment strategies. These applications can significantly improve the accuracy and speed of financial processes, reducing operational costs and increasing profitability. Furthermore, AI can help financial institutions identify and mitigate potential risks, safeguarding both the institutions and their customers.

AI and Environmental Sustainability

AI is proving to be a valuable tool in tackling environmental challenges. AI algorithms can analyze vast datasets of environmental data, such as climate patterns, pollution levels, and resource consumption, to identify trends and predict future outcomes. This data-driven approach can help researchers and policymakers develop more effective strategies for environmental conservation and sustainability. By identifying patterns and predicting outcomes, AI can support more informed decision-making in areas like resource management and emissions reduction. Moreover, AI can optimize energy consumption and streamline waste management, promoting a more sustainable future.

Read more about Robotics for automated handling of delicate products

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit