Optimizing Production Flows with Digital Twin Technology

Introduction to Digital Twins in Manufacturing

Introduction to Digital Twins in Manufacturing

Digital twins are virtual representations of physical assets, processes, or systems. In the manufacturing sector, this translates to a digital replica of a machine, a production line, or even an entire factory. This digital twin captures all the critical data from the physical counterpart, including its design specifications, operating parameters, performance metrics, and maintenance history. The potential for optimizing production flows is significant, as digital twins provide a platform for simulating various scenarios and predicting potential issues before they impact real-world operations.

Key Components of a Manufacturing Digital Twin

A comprehensive digital twin encompasses several interconnected components. These include a detailed model of the physical asset, real-time data feeds from sensors embedded in the physical system, and sophisticated algorithms that process the data to provide insights and predictions. The model itself must be highly accurate, reflecting the physical dimensions, material properties, and operational characteristics of the asset being represented. This allows for a nuanced understanding of the system's behavior.

Data Acquisition and Integration

The core of a digital twin is the continuous acquisition and integration of data. This data comes from various sources, such as sensors on machinery, production logs, maintenance records, and even external factors like weather patterns. Effective integration ensures all relevant information is accessible and utilized by the digital twin's algorithms, providing a holistic view of the system's performance.

Predictive Maintenance and Proactive Problem Solving

One of the most compelling applications of digital twins is in predictive maintenance. By analyzing historical data and real-time sensor readings, the digital twin can anticipate potential equipment failures, allowing for proactive maintenance interventions. This approach minimizes downtime, reduces unexpected costs, and improves overall production efficiency. Furthermore, the digital twin can identify patterns and anomalies that may indicate underlying issues, enabling proactive problem-solving.

Simulation and Optimization of Production Flows

Digital twins empower manufacturers to simulate different production scenarios without impacting real-world operations. This allows them to experiment with various parameters such as material flow, workforce scheduling, and equipment configurations to optimize production flows. By testing these scenarios virtually, manufacturers can identify bottlenecks, enhance efficiency, and improve overall output in a risk-free environment.

Real-time Monitoring and Control

Digital twins enable real-time monitoring of production processes, providing insights into the performance of equipment and the overall operational efficiency. This real-time feedback loop allows for immediate adjustments to production parameters, ensuring optimal performance and minimizing disruptions. The ability to monitor and control processes in real-time is crucial for maintaining high quality and consistent output.

Benefits and Future Trends in Manufacturing

The benefits of digital twins extend beyond predictive maintenance and simulation. They contribute to increased efficiency, enhanced safety, and reduced operational costs. Future trends in manufacturing digital twins include the integration of artificial intelligence (AI) and machine learning (ML) for advanced data analysis and more sophisticated predictive capabilities. This will lead to even more accurate predictions and more proactive interventions in production processes, ultimately propelling manufacturing into a new era of efficiency and innovation.

Predictive Maintenance and Proactive Problem Solving

Predictive Maintenance Strategies

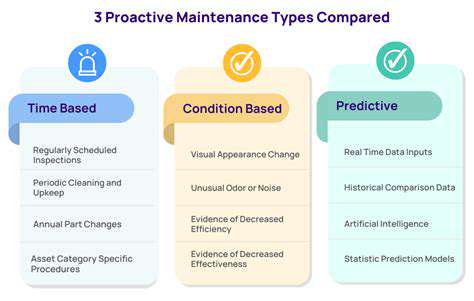

Predictive maintenance (PdM) is a proactive approach to equipment maintenance that focuses on anticipating potential equipment failures before they occur. This contrasts with reactive maintenance, which addresses failures only after they happen. PdM leverages data analysis and advanced analytics to identify patterns and anomalies in equipment performance, allowing for timely interventions and minimizing unplanned downtime. By monitoring key performance indicators (KPIs), such as vibration levels, temperature, and pressure, PdM systems can forecast when maintenance is needed, enabling organizations to schedule maintenance during optimal periods and avoid costly and disruptive breakdowns.

A key aspect of PdM is the collection and analysis of vast amounts of data from various sources, including sensors, operational logs, and historical maintenance records. Sophisticated algorithms and machine learning models are employed to process this data, identifying patterns and trends that indicate potential failures. This data-driven approach enables organizations to make informed decisions about maintenance schedules, minimizing unnecessary interventions while ensuring that critical equipment remains operational.

Benefits of Predictive Maintenance

Implementing predictive maintenance strategies offers a wide range of benefits, including significant cost savings and increased operational efficiency. By preventing equipment breakdowns, organizations can reduce unplanned downtime, leading to increased productivity and output. This translates into tangible financial benefits, such as reduced repair costs, lower inventory levels, and improved asset utilization. Reduced downtime also translates to increased safety and fewer risks for employees and the surrounding environment.

Predictive maintenance also enhances the overall reliability and lifespan of equipment. By proactively addressing potential issues, organizations can maintain equipment in optimal condition, extending its operational life and reducing the need for costly replacements. This proactive approach to maintenance fosters a culture of continuous improvement, allowing organizations to optimize their maintenance strategies over time and achieve even greater operational efficiencies.

Challenges of Implementing Predictive Maintenance

While predictive maintenance offers significant advantages, implementing these strategies can present certain challenges. One key challenge involves the significant investment required for advanced sensors, data collection systems, and sophisticated analytics tools. The complexity of the data analysis process and the need for skilled personnel to interpret the results also pose challenges. The integration of PdM systems with existing operational processes and infrastructure can also be a complex undertaking.

Another challenge is the need for accurate and reliable data. Inaccurate or incomplete data can lead to flawed predictions and ineffective maintenance strategies. Ensuring data quality and consistency throughout the system is crucial for successful PdM implementation. Establishing a strong data management system is essential to address this challenge, ensuring that the data collected is accurate, reliable, and readily accessible for analysis.

Optimizing Production Schedules and Resource Allocation

Optimizing Production Schedules for Efficiency

Efficient production scheduling is crucial for maximizing output while minimizing costs and delays. A well-defined schedule ensures resources are allocated effectively, leading to improved productivity and reduced waste. This involves considering various factors such as production capacity, material availability, and demand forecasting to create a realistic and adaptable plan.

By proactively addressing potential bottlenecks and scheduling tasks in a logical sequence, companies can significantly reduce downtime and improve overall operational efficiency. This proactive approach also fosters a better understanding of resource utilization, enabling better decision-making for future production runs.

Utilizing Data-Driven Insights for Scheduling

Implementing data-driven insights is essential for optimizing production schedules. Analyzing historical production data, including machine downtime, material lead times, and labor efficiency, provides valuable information for refining scheduling algorithms. This data-driven approach allows for more accurate predictions and adjustments to the schedule based on real-time feedback.

By incorporating data analysis into the scheduling process, companies can identify trends and patterns that might otherwise be missed, leading to more effective allocation of resources and reduced production bottlenecks.

Considering External Factors in the Scheduling Process

Production schedules should not be isolated from external factors that can impact production. These factors may include fluctuating raw material costs, supply chain disruptions, and unexpected equipment failures. Adaptability is key, and production schedules need to be flexible enough to accommodate these changes without significant disruptions to the overall process.

Implementing Agile Scheduling Strategies

Adopting agile scheduling strategies allows for more responsive adjustments to changing demands and unforeseen circumstances. This approach emphasizes flexibility and the ability to adapt production schedules in real time. This allows companies to quickly respond to shifts in customer demand and maintain a competitive edge in the market. These strategies also enable faster turnaround times for new product introductions and better inventory management.

The Role of Technology in Modern Production Scheduling

Modern production scheduling relies heavily on technology for efficiency and accuracy. Software applications provide tools for planning, monitoring, and optimizing production schedules, enabling real-time adjustments and better communication across departments. Advanced software solutions allow for complex simulations and scenarios to be explored before implementation, minimizing risk and maximizing efficiency. Integration with other systems, like ERP and CRM, provides a holistic view of the entire production process.

Improving Quality Control and Reducing Waste

Streamlining Processes for Enhanced Efficiency

Improving quality control and reducing waste are crucial components of optimizing production flows. By implementing streamlined processes, businesses can identify and eliminate bottlenecks, leading to significant improvements in efficiency and productivity. This involves analyzing existing workflows, identifying areas for improvement, and implementing changes that minimize errors and rework. Streamlining processes often involves re-evaluating the steps involved in each stage of production, seeking ways to eliminate unnecessary steps and consolidate tasks. This approach not only improves the quality of the final product but also reduces the overall time required to complete the production cycle.

A key aspect of streamlining is the use of technology. Implementing digital tools and systems can automate repetitive tasks, track production progress in real-time, and provide valuable data insights. This data can be used to identify patterns, predict potential issues, and make data-driven decisions to further optimize the production flow. Real-time monitoring of production metrics allows for quick identification of deviations from established standards, enabling proactive intervention to prevent defects and waste.

Implementing Robust Quality Control Measures

Effective quality control is essential for minimizing waste and ensuring high-quality products. This involves establishing clear standards and procedures for each stage of production, ensuring that all employees understand and adhere to these guidelines. Implementing rigorous testing and inspection protocols at various stages of the process helps to identify and rectify issues early on, preventing costly defects from reaching the end product. This proactive approach not only enhances the quality of the final product but also reduces the need for costly rework and returns.

A crucial aspect of robust quality control is the use of preventative measures. By identifying potential sources of errors and implementing controls to mitigate them, companies can significantly reduce the likelihood of defects. These preventative measures can include training programs for employees, improved equipment maintenance schedules, and the implementation of clear communication protocols throughout the production process. By focusing on prevention, companies can save time, resources, and ultimately, money.

Implementing a robust quality control system also involves the careful selection and training of employees. Dedicated personnel with the appropriate skills and knowledge are crucial for ensuring the accuracy and effectiveness of quality checks. Training employees on the latest quality control methods, providing them with the necessary tools and resources, and fostering a culture of quality within the workforce are all vital elements in achieving the desired outcomes.

Regular audits and reviews of the quality control system are essential for ensuring its continued effectiveness. This allows for adjustments to be made as needed, based on the feedback and data collected. By regularly evaluating and refining the quality control system, companies can adapt to changing circumstances and ensure that the system remains relevant and effective in achieving their quality goals.

Read more about Optimizing Production Flows with Digital Twin Technology

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit