Data Lineage Tools for Supply Chain Auditability and Transparency

Enhancing Supply Chain Resilience and Efficiency

Understanding the Criticality of Supply Chain Resilience

A robust and resilient supply chain is no longer a desirable feature but a critical necessity in today's complex and rapidly changing global economy. Disruptions, whether natural disasters, geopolitical events, or pandemics, can have devastating consequences for businesses, impacting their ability to deliver products and services to customers. Understanding the vulnerabilities within your supply chain is the first step toward building resilience. Identifying potential risks and developing mitigation strategies is crucial for minimizing the impact of unforeseen circumstances.

Supply chain resilience isn't just about reacting to problems; it's about proactively anticipating and preventing them. This involves careful planning, diversification of suppliers, and building strong relationships with partners.

Diversifying Supplier Networks

Focusing on a single supplier can create significant vulnerabilities. Depending on a single source for critical components or raw materials leaves your entire operation exposed to disruptions. Diversifying your supplier network minimizes risk by spreading the load across multiple reliable sources. This not only safeguards against supply shortages but also allows for negotiating better terms and potentially reducing costs in the long run.

Thorough due diligence and ongoing monitoring of potential suppliers are essential. Evaluating their capacity, financial stability, and ethical practices are all critical considerations in building a robust and reliable network.

Improving Visibility and Control

Gaining complete visibility into your supply chain processes is essential for effective management. Implementing technologies and systems that track inventory, monitor transportation, and provide real-time updates on the movement of goods allows for proactive identification of potential bottlenecks or disruptions. This proactive approach enables timely adjustments and minimizes the impact of unforeseen events.

By leveraging data analytics and implementing sophisticated tracking systems, companies can anticipate potential problems and develop contingency plans.

Investing in Technology and Automation

Integrating advanced technologies like AI, machine learning, and blockchain into your supply chain can significantly enhance its resilience. These tools can help predict and mitigate risks, automate processes, and improve overall efficiency. Automation can reduce manual errors and increase speed, which are critical for maintaining a swift response to disruptions.

Building Strong Relationships with Stakeholders

Collaboration and strong relationships with suppliers, distributors, and customers are vital to building a resilient supply chain. Open communication, shared goals, and mutual respect foster trust and cooperation, enabling faster responses to challenges and smoother transitions during difficult times. Trust and transparency among all parties are essential for effective collaboration and quick problem-solving.

Proactive communication and joint problem-solving are key aspects of building strong, resilient partnerships. Developing clear communication protocols and regularly scheduled meetings will help maintain open lines of communication and foster a culture of collaboration.

Implementing Contingency Plans and Disaster Recovery

Proactively developing contingency plans for various potential disruptions is crucial for ensuring supply chain resilience. These plans should outline alternative sourcing strategies, backup logistics routes, and communication protocols in the event of unforeseen circumstances. Having a detailed disaster recovery plan in place is critical to ensuring business continuity during times of crisis.

Regularly testing and updating these plans is essential to ensure their effectiveness. Simulating scenarios and practicing responses will help teams become familiar with the procedures and ensure they are ready to implement them when needed.

Read more about Data Lineage Tools for Supply Chain Auditability and Transparency

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

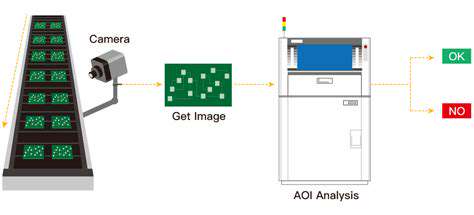

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit