Vertical Beehive Maintenance for Urban Beekeeper Couples

Regular Inspections: Importance and Frequency

Consistent check-ups form the backbone of any well-functioning system, whether we're talking about mechanical equipment, architectural structures, or even living ecosystems. By catching small issues before they escalate, you're not just saving money—you're extending the lifespan of your entire operation. When you spot a potential problem early, you have more options for addressing it, which means less downtime and better overall performance. This forward-thinking approach pays dividends over time.

How often you should inspect depends entirely on what you're examining and where it's located. Heavy-use equipment in harsh environments needs more frequent attention than lightly used items in controlled settings. The smartest operators create customized inspection calendars that account for all relevant variables—usage patterns, environmental stressors, and system complexity. One-size-fits-all schedules often miss critical maintenance windows.

Types of Inspections

Inspection methods vary as much as the systems they evaluate. Basic visual examinations serve as the first line of defense, where trained eyes scan for obvious signs of wear, damage, or irregular conditions. More sophisticated evaluations might involve precision measurements, performance testing, or specialized diagnostics conducted by certified technicians. This spectrum of approaches ensures thorough evaluations across different scenarios.

From quick visual scans to comprehensive technical audits, inspection intensity should match the criticality of the system being examined. This tiered approach allows maintenance teams to allocate resources efficiently while still catching potential issues early.

Inspection Procedures and Documentation

Consistency matters in inspections—that's why written protocols make all the difference. These guidelines should cover everything from pre-inspection preparations to final reporting requirements. Detailed checklists prevent oversight, while photographic evidence and descriptive notes create valuable historical records. Well-documented inspections transform random checks into strategic data points that reveal patterns over time.

Those inspection logs become more valuable with each passing year. They help identify recurring issues, track equipment degradation rates, and justify maintenance budgets. In legal or insurance situations, thorough documentation often makes the difference between successful claims and costly disputes.

Safety Considerations During Inspections

No inspection justifies compromising safety. Proper protective gear—from hard hats to respirators—should always be worn based on the specific hazards present. Established safety protocols exist for good reason: they prevent injuries and create controlled conditions for accurate assessments. This includes proper lockout/tagout procedures when working with energized equipment.

A safe inspection environment protects both personnel and the systems being examined. Rushed or careless inspections can cause additional damage while failing to identify actual problems. Safety measures aren't bureaucratic hurdles—they're essential components of effective maintenance practices.

Honey Harvesting and Hive Management for Urban Couples

Honey Extraction Techniques

Harvesting honey requires balancing efficiency with comb preservation. While modern electric extractors speed up the process, they can sometimes damage delicate comb structures. The best method depends on your specific circumstances—hive size, honey type, and personal preferences all factor into the decision. Smaller operations might prefer manual methods that allow for greater control and gentler handling.

Traditional extraction methods, though slower, often produce superior comb integrity and honey quality. The extra time investment frequently pays off in reduced comb damage and easier hive recovery post-harvest.

Hive Maintenance and Inspection

Healthy hives require regular monitoring—think of it as preventive healthcare for your bees. During inspections, watch for disease symptoms, pest activity, or other abnormalities. Early detection makes treatment easier and prevents colony collapse. Proper hive ventilation ranks among the most overlooked yet critical factors in bee health. Good airflow prevents moisture buildup that can lead to mold and disease.

A well-organized hive functions better in every way. Ensure adequate space for brood development and sufficient honey/pollen stores. Consistent inspection routines help beekeepers anticipate problems rather than react to crises.

Colony Health and Disease Prevention

Vigilance separates successful beekeepers from frustrated ones. Regular health checks should screen for varroa mites, foulbrood, and other common threats. Many experienced keepers recommend establishing baseline health metrics for each hive—this makes abnormalities easier to spot. Early intervention often means the difference between losing a few bees and losing the entire colony.

Honey Storage and Preservation

Proper storage maintains honey's natural qualities almost indefinitely. While honey naturally resists spoilage, optimal conditions—cool, dark, and sealed—preserve flavor and texture. Clear labeling creates professional presentation while providing important information like harvest dates and floral sources. Thoughtful packaging enhances both shelf life and customer appeal.

Many urban beekeepers find that proper storage solutions pay for themselves through reduced waste and higher customer satisfaction. Investing in quality containers demonstrates professionalism while protecting your product's integrity.

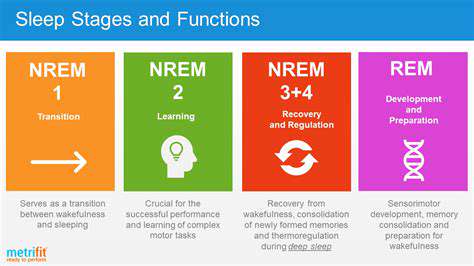

Quality sleep forms the foundation of good health, influencing everything from mental sharpness to emotional stability. Maintaining consistent sleep schedules—even on weekends—helps regulate circadian rhythms, leading to more restorative sleep. Evening routines signal the brain to wind down, while avoiding stimulants near bedtime prevents sleep disruption. These simple practices compound over time into significant health benefits.

Winterization Strategies for Vertical Beehives in Urban Environments

Optimizing Hive Placement for Winter Survival

Strategic hive positioning dramatically impacts winter survival rates. South-facing locations maximize precious winter sunlight while natural windbreaks—buildings, fences, or landscaping—reduce heat loss. Urban beekeepers should study local microclimates; sometimes moving a hive just 20 feet can create significantly better conditions. Thoughtful placement reduces the energy bees expend on temperature regulation, conserving their winter stores.

Insulation Strategies for Enhanced Winter Protection

Effective insulation acts like a thermal blanket for hives. Specialized materials or natural options like straw create critical barriers against cold. Layered insulation often works best—it traps more air pockets while allowing moisture regulation. The goal isn't necessarily maximum warmth, but rather temperature stability that prevents drastic fluctuations stressing the colony.

Providing Adequate Food Stores for Winter Survival

Winter bee survival hinges on sufficient honey reserves. Urban environments often lack late-season forage, making supplemental feeding sometimes necessary. Monitor stores carefully—it's better to intervene early than discover an empty hive in February. Many experienced beekeepers leave extra frames or provide fondant as emergency rations during the coldest months.

Controlling Temperature Fluctuations

Bees handle consistent cold better than temperature swings. Strategic placement, proper insulation, and sometimes even thermal mass (like water barrels) help moderate hive temperatures. Sudden thaws followed by freezes prove particularly dangerous—they can trigger premature brood rearing that strains winter resources.

Managing Pests and Diseases

Winter weakens colonies, making them vulnerable to pests and pathogens. Fall treatments for varroa mites and other threats give bees their best chance. Healthy colonies going into winter have dramatically higher survival rates than compromised ones. Regular monitoring continues even in cold months—quick action during warm spells can save struggling hives.

Protecting from Extreme Weather Events

Urban environments create unique weather challenges—wind tunnels between buildings, heavy snow loads, or ice accumulation. Physical barriers, secure fastenings, and sometimes temporary covers provide necessary protection. Preventative measures always prove easier than emergency interventions during storms.

Monitoring the Colony Throughout Winter

Winter beekeeping means listening more than looking. Quick checks during mild periods assess food stores and colony activity without causing excessive heat loss. Knowing when to intervene—and when to leave alone—comes with experience but fundamentally relies on attentive monitoring.

Building a Sustainable Urban Beekeeping Partnership

Understanding the Benefits of Urban Beekeeping

City beekeeping creates unexpected ecological connections, supporting urban biodiversity beyond just honey production. These pollinators enhance local gardens, parks, and even balcony plants, creating greener, more resilient urban ecosystems. The educational value reaches beyond apiaries—it changes how communities view their relationship with nature. Shared experiences around beekeeping often spark broader environmental awareness and action.

Vertical Beehive Maintenance Strategies

Vertical hives present unique management challenges requiring adapted techniques. Space constraints demand precise frame spacing and careful swarm prevention measures. Innovative tools like long-handled smokers and specially designed frame lifters make vertical hive inspections safer and more effective. Regular maintenance prevents small issues from becoming major problems in these compact systems.

Partnering with Local Communities for Sustainability

Successful urban apiaries thrive through community engagement. Local businesses might host hives, schools could incorporate beekeeping into STEM programs, and neighborhood associations can help monitor hive health. These partnerships create shared ownership that benefits both bees and people. When communities value their pollinators, they're more likely to support pollinator-friendly policies and practices.

Read more about Vertical Beehive Maintenance for Urban Beekeeper Couples

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit