Robotics in warehousing: Boosting efficiency and cutting costs

The Rise of Robotic Automation in Warehousing

The Growing Importance of Efficiency

Robotic automation is rapidly transforming industries across the globe, driven by a relentless pursuit of greater efficiency. Companies are increasingly recognizing the significant advantages of automating tasks that are repetitive, time-consuming, or potentially hazardous for human workers. This shift towards automation is not simply about replacing human labor; it's about optimizing workflows and freeing up human employees to focus on higher-level tasks that require creativity, critical thinking, and complex problem-solving.

Automation streamlines processes, leading to reduced production times and increased output. This efficiency translates directly to cost savings, making robotic systems an attractive investment for businesses of all sizes. The benefits extend beyond financial gains, however, as automation also contributes to improved product quality and consistency.

Technological Advancements Fueling the Trend

The development of increasingly sophisticated robotic systems, coupled with advancements in artificial intelligence (AI) and machine learning (ML), has significantly accelerated the adoption of robotic automation. These technologies enable robots to perform more complex tasks with greater precision and adaptability, making them increasingly valuable assets in various sectors.

The integration of sensors, advanced control systems, and sophisticated programming languages allows robots to interact with their environment in more nuanced ways. This expanded functionality has opened up new possibilities for automation in areas previously considered impractical or even impossible.

Impact on the Workforce and Future of Work

The integration of robotic automation into the workforce is a complex issue, raising questions about the future of work. While some jobs may be displaced, the introduction of these technologies also creates new opportunities in areas like robotic maintenance, programming, and system optimization.

The workforce is likely to adapt and transition to roles that complement robotic automation rather than being replaced entirely. A crucial element of this transition will be upskilling and reskilling programs to equip workers with the necessary skills for the evolving job market.

The shift towards collaborative robots (cobots) that work alongside humans is one example of how robotic automation can enhance human capabilities, leading to more efficient and safer workplaces.

Economic and Societal Implications

The rise of robotic automation has far-reaching economic and societal implications. Economically, it can lead to increased productivity and potentially higher standards of living. However, concerns about job displacement and income inequality require careful consideration and proactive solutions.

Societal implications extend beyond the workplace, encompassing issues like the ethical use of robots in various industries. This includes the need for responsible development and deployment of these technologies to mitigate potential negative consequences.

Optimizing Inventory Management and Storage

Optimizing Inventory Accuracy

Accurate inventory tracking is crucial for efficient warehousing operations. Robotics play a pivotal role in achieving this by automating tasks like picking, packing, and scanning items. This automated data collection and verification significantly reduces human error, leading to more precise inventory records. Real-time updates minimize discrepancies between physical stock and the inventory management system, allowing for better forecasting and decision-making, ultimately preventing stockouts and overstocking issues.

Implementing robotic systems for inventory auditing and cycle counting allows for more frequent and thorough checks. This proactive approach ensures that the inventory data is consistently accurate, enabling businesses to make well-informed decisions regarding production, procurement, and sales strategies. Enhanced inventory accuracy translates directly to improved profitability and reduced operational costs.

Improving Storage Efficiency

Warehouse storage space is often a valuable asset that needs to be utilized effectively. Robotic systems can optimize storage by implementing automated storage and retrieval systems (AS/RS). These systems can store items vertically, maximizing space utilization and allowing for easy access to goods at any location. This increased storage density translates to a more compact and efficient warehouse layout, potentially freeing up valuable real estate.

Robotic solutions can also automate the movement of goods within the warehouse. Automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS) can transport items from storage locations to pick stations, and vice-versa, with speed and precision. This streamlines the workflow and reduces the time spent on manual material handling, leading to increased productivity and faster order fulfillment times.

Boosting Warehouse Productivity and Safety

Robotics automation significantly boosts warehouse productivity by handling repetitive tasks, such as picking, packing, and transporting items. This frees up human workers to focus on more complex and strategic tasks, leading to a more efficient and productive workforce. The reduction in manual labor also contributes to a safer working environment, minimizing the risk of injuries associated with heavy lifting and strenuous activities. This can lead to lower worker compensation costs and a more positive and motivated workforce.

By automating high-risk tasks, robotic systems enhance worker safety. This includes tasks like loading and unloading goods, which can be hazardous for human workers. The reduced physical strain on employees, along with improved workflow organization, leads to enhanced safety standards and a more secure working environment. Robots can operate in hazardous or challenging environments, further enhancing overall warehouse safety.

Read more about Robotics in warehousing: Boosting efficiency and cutting costs

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

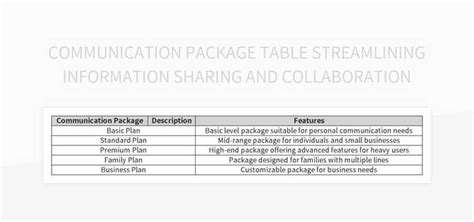

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit