Machine Learning for Supply Chain Route Optimization

Introduction to Supply Chain Route Optimization

Understanding the Importance of Route Optimization

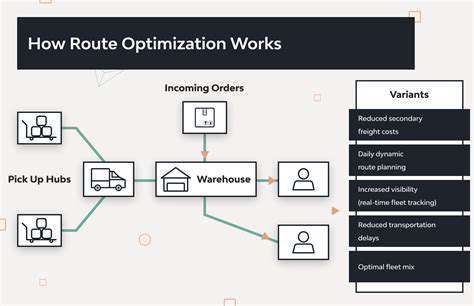

Supply chain route optimization is crucial for businesses seeking to minimize costs and maximize efficiency. By strategically planning and managing transportation routes, companies can significantly reduce fuel consumption, decrease delivery times, and lower overall operational expenses. Optimizing routes isn't just about saving money; it's about enhancing customer satisfaction by ensuring timely and reliable deliveries. Effective route optimization allows businesses to react more quickly to changing market demands and maintain a competitive edge in today's dynamic business landscape. This process involves careful consideration of various factors, including distance, traffic patterns, delivery windows, and vehicle capacity.

Route optimization is a core component of a robust supply chain strategy, directly impacting profitability and customer experience. By identifying and addressing inefficiencies in the transportation network, companies can improve their logistical performance and gain a competitive advantage. This optimization process involves complex calculations and algorithms to determine the most efficient routes, taking into account various constraints and objectives. The ultimate goal is to achieve cost savings, reduced lead times, and heightened delivery reliability, ultimately bolstering the overall performance of the supply chain. This optimization process is not a one-time event; it requires continuous monitoring and adaptation to changing circumstances.

Leveraging Machine Learning for Enhanced Optimization

Machine learning algorithms provide powerful tools for supply chain route optimization. These algorithms can analyze vast amounts of data, including historical delivery data, real-time traffic information, weather patterns, and even delivery constraints, to identify optimal routes. By considering these factors, machine learning models can predict potential delays and adjust routes accordingly, ensuring on-time deliveries and minimizing disruptions. This predictive capability is critical in today's complex supply chains, allowing businesses to adapt swiftly to changing conditions and maintain a high level of service.

Machine learning models can also consider factors like vehicle capacity, driver availability, and delivery windows. This comprehensive approach allows for the creation of more sophisticated and adaptable route plans. The integration of machine learning into route optimization systems allows for dynamic adjustments in real-time, responding to unforeseen events like traffic jams or unexpected delays. This responsiveness is essential for maintaining a seamless and efficient supply chain, ultimately leading to a better customer experience.

Challenges and Considerations in Implementing ML-Driven Optimization

While machine learning offers significant potential for supply chain route optimization, implementing these systems poses certain challenges. One crucial aspect is the need for substantial amounts of high-quality data. Accurate and comprehensive data is essential for training robust machine learning models. Furthermore, integrating machine learning algorithms into existing supply chain systems can be complex and require significant investment in new technologies and expertise. Companies need to carefully assess the potential benefits against the costs and challenges to make informed decisions about implementation.

Another important consideration is the need for skilled personnel to manage and maintain the machine learning systems. Data scientists and analysts with expertise in machine learning algorithms are required to ensure the models are accurate and perform as expected. Security and data privacy concerns are also crucial elements to address before implementation. Maintaining the confidentiality and integrity of sensitive data is paramount in a supply chain setting. Addressing these challenges proactively is essential for successful implementation and realizing the full potential of machine learning-driven route optimization.

Finally, ensuring the models adapt to changing conditions and remain accurate over time requires continuous monitoring and refinement. Adaptability is key in the ever-evolving landscape of supply chains. Regular updates and adjustments to the models are necessary to optimize the algorithms and ensure the system remains effective. The supply chain environment is in constant flux, and the models need to adapt to these changes for continued effectiveness.

The Role of Machine Learning in Route Optimization

The Foundation of Machine Learning in Robotics

Machine learning (ML) is rapidly transforming the field of robotics, enabling robots to learn from data and adapt to new situations without explicit programming. This allows robots to perform complex tasks and overcome challenges that were previously impossible. This fundamental shift in robotics moves it away from rigid, pre-programmed systems towards more flexible, adaptable ones. The ability for robots to learn and improve over time is crucial for their deployment in diverse environments and applications.

The core concept behind machine learning in robotics involves feeding robots large datasets of information, allowing them to identify patterns, make predictions, and ultimately, improve their performance. This process is crucial for tasks like object recognition, navigation, and manipulation, all essential for a robot's functionality.

Data Acquisition and Preparation

A critical component of successful machine learning in robotics is the acquisition and preparation of high-quality data. This data might include sensor readings, images, or even human demonstrations of desired actions. Effectively processing and labeling this data is paramount to training accurate and reliable machine learning models.

Careful consideration must be given to the representativeness and diversity of the data to ensure the model generalizes well to unseen situations. Poor data quality can lead to inaccurate predictions and unreliable robot performance.

Algorithm Selection for Tasks

Choosing the appropriate machine learning algorithm is essential for achieving desired outcomes in robotic tasks. Different algorithms excel at different types of data and tasks. For instance, supervised learning is ideal for tasks where the desired output is known, while unsupervised learning is beneficial for discovering hidden patterns in data. The selection of the algorithm is often a critical factor in the success of the entire robotic system.

Model Training and Optimization

Training machine learning models for robotics involves feeding the prepared data into the chosen algorithm, allowing the model to learn the underlying relationships and patterns. This process often requires significant computational resources. Optimization techniques are crucial to ensure efficient training and accurate model performance. This involves adjusting parameters and refining the model to minimize errors and maximize accuracy.

Evaluation and Validation

Evaluating the performance of a trained machine learning model in a robotic system is essential for ensuring its reliability and safety. This evaluation often involves testing the model on a separate dataset from the training data. Thorough validation and testing are crucial to prevent unexpected behavior or failures in real-world deployments.

Real-World Applications and Deployment

The application of machine learning in robotics spans a wide range of industries, from manufacturing and healthcare to agriculture and space exploration. Robots equipped with machine learning capabilities are capable of handling increasingly complex tasks and environments. Successful deployment requires careful consideration of safety, reliability, and ethical implications.

From navigating intricate environments to performing delicate surgeries, machine learning empowers robots to adapt and excel in diverse and challenging settings. The integration of machine learning into robotics promises a future where robots can assist humans in ways previously unimaginable.

Ethical Considerations and Future Directions

As machine learning becomes more integrated into robotics, ethical considerations become increasingly important. Issues like bias in data, robot autonomy, and job displacement need careful consideration. Addressing these challenges is crucial to ensure responsible and beneficial integration of these technologies. Future research should focus on developing robust and explainable machine learning models for robotics, ensuring safety and ethical deployment.

Further advancements in machine learning and robotics will undoubtedly lead to more sophisticated and capable robots, pushing the boundaries of what's possible. The future of robotics is deeply intertwined with the continued evolution of machine learning.

Types of Machine Learning Algorithms for Route Optimization

Supervised Learning for Route Optimization

Supervised learning algorithms are crucial for route optimization tasks because they learn from labeled data. This means that the algorithm is trained on examples of routes, along with their associated costs or performance metrics (e.g., travel time, fuel consumption, delivery time). By analyzing these examples, the algorithm can identify patterns and relationships between various factors influencing route efficiency, such as traffic conditions, distance, and delivery points. This enables the algorithm to predict optimal routes for new delivery or transportation scenarios, leading to significant improvements in efficiency and cost savings.

Examples of supervised learning algorithms frequently used in route optimization include Support Vector Machines (SVMs) and decision trees. SVMs excel at classifying routes based on various criteria, while decision trees provide a clear, rule-based approach for route selection. These methods allow for the development of sophisticated models that can adapt to dynamic conditions, such as changing traffic patterns or varying customer demands, leading to more robust and adaptable route optimization solutions.

Unsupervised Learning for Route Clustering

Unsupervised learning algorithms, unlike supervised methods, work with unlabeled data, enabling route optimization based on inherent patterns and groupings. These algorithms are particularly useful for identifying clusters of similar routes or delivery patterns. For example, an algorithm can group routes based on geographical proximity, frequency of deliveries, or similar delivery durations. This clustering can lead to the creation of optimized delivery zones, allowing for more efficient resource allocation and reduced logistical costs.

Clustering algorithms, such as k-means and hierarchical clustering, can be employed to group similar routes. By analyzing and grouping these routes, logistics companies can gain valuable insights into optimal delivery zones, allowing them to tailor their operations to specific geographical areas. This approach also allows for the identification of potential bottlenecks in the delivery process, enabling preventative measures and continuous improvement in the logistics network.

Reinforcement Learning for Dynamic Route Optimization

Reinforcement learning (RL) algorithms are powerful tools for dynamic route optimization, especially in scenarios with evolving conditions. These algorithms learn through trial and error, interacting with an environment to maximize a reward function. In route optimization, the environment can represent real-time traffic conditions, delivery deadlines, and vehicle capacities. The algorithm learns optimal routes by iteratively adjusting its strategy based on the feedback it receives from the environment, maximizing the reward, which could be minimizing delivery time or cost.

RL algorithms can adapt to real-time changes in traffic conditions, providing a robust approach to dynamic route optimization. This adaptability is crucial in situations where traffic patterns are unpredictable or where unexpected events arise. By learning from past actions and their consequences, these algorithms can refine their route optimization strategies, leading to more efficient and cost-effective delivery solutions in real-world applications.

Implementing ML for Supply Chain Route Optimization

Implementing Machine Learning for Enhanced Supply Chain Resilience

Machine learning (ML) algorithms offer significant potential for enhancing supply chain resilience by enabling proactive identification and mitigation of potential disruptions. By analyzing vast datasets encompassing historical trends, external factors, and internal operational data, ML models can predict potential bottlenecks and disruptions with greater accuracy than traditional methods. This predictive capability allows companies to implement preemptive strategies, reducing the impact of unforeseen events and maintaining operational continuity.

Predictive Analytics for Demand Forecasting

Accurate demand forecasting is crucial for optimizing inventory levels, production schedules, and resource allocation in supply chains. ML models, trained on historical sales data, external economic indicators, and even social media trends, can provide highly accurate demand forecasts, allowing businesses to proactively adjust their operations to meet fluctuating demand. This proactive approach minimizes excess inventory costs and ensures sufficient stock availability during peak periods, ultimately leading to greater efficiency and profitability.

Optimizing Inventory Management

Maintaining optimal inventory levels is a significant challenge in supply chains. ML algorithms can be instrumental in dynamically adjusting inventory levels based on real-time demand fluctuations, supplier lead times, and predicted disruptions. This dynamic approach minimizes the risk of stockouts or overstocking, ensuring that the right products are available at the right time and place. This optimization directly impacts costs and reduces the risk of significant financial losses due to either excess inventory or product shortages.

Improving Supplier Relationship Management

Building strong and reliable supplier relationships is critical for a resilient supply chain. ML models can analyze supplier performance data, delivery history, and risk factors to identify potential issues and opportunities for improvement. Through this data-driven approach, companies can proactively address potential supplier disruptions and negotiate more favorable contracts. This leads to a more robust and trustworthy supplier network. This approach also allows for the identification of potentially problematic suppliers early in the process, preventing costly disruptions later.

Real-time Monitoring and Alerting

Real-time monitoring of key supply chain metrics using ML algorithms is essential for proactive disruption management. ML models can analyze data from various sources, including sensor data, logistics tracking, and social media sentiment, to identify emerging trends and potential disruptions in real-time. This allows companies to receive immediate alerts and take swift corrective actions, minimizing the impact of unexpected events and maintaining business continuity. This early intervention is crucial in avoiding significant delays and maintaining the flow of goods throughout the supply chain.

Read more about Machine Learning for Supply Chain Route Optimization

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit