Robotics for automated container unloading

Optimizing Workflow and Warehouse Integration

Streamlining Processes for Efficiency

Optimizing warehouse workflows involves a multifaceted approach focusing on streamlining processes to maximize efficiency and minimize waste. This includes analyzing current procedures, identifying bottlenecks, and implementing innovative solutions. By carefully examining each step in the receiving, storage, picking, packing, and shipping processes, potential areas for improvement can be highlighted, leading to significant gains in productivity and reduced operational costs. This meticulous evaluation necessitates a deep understanding of the specific needs and demands of the warehouse operations, considering factors such as product types, storage requirements, and order volumes. Implementing standardized procedures and utilizing technology-driven solutions can further enhance workflow efficiency. Ultimately, a streamlined workflow contributes to a more organized and productive warehouse environment.

Critical to this process is the identification of key performance indicators (KPIs). Tracking these metrics provides a clear picture of the effectiveness of the optimized workflow. By measuring metrics such as order fulfillment time, picking accuracy, and inventory turnover, warehouse managers can readily assess the impact of implemented changes and make necessary adjustments. This continuous monitoring and evaluation ensures that the optimization strategies remain aligned with the overall business goals and continually improve warehouse performance.

Utilizing Technology for Enhanced Productivity

The modern warehouse environment benefits significantly from integrating advanced technologies. Implementing automated systems, such as robotic process automation (RPA), can drastically improve efficiency in handling tasks such as inventory management, order processing, and picking. This integration not only reduces manual labor but also minimizes errors, leading to more accurate and faster order fulfillment. The automation process allows warehouse personnel to focus on more complex and strategic tasks, maximizing their expertise and skills. For instance, automated storage and retrieval systems (AS/RS) can significantly reduce the time spent locating and retrieving products, resulting in considerable gains in throughput.

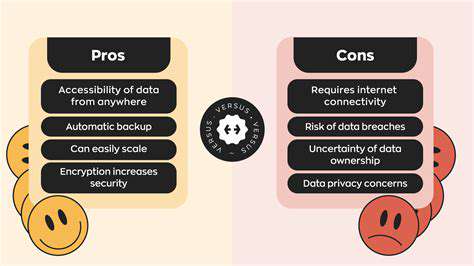

Warehouse management systems (WMS) are another crucial component in optimizing warehouse operations. These systems provide a centralized platform for managing and tracking inventory, orders, and logistics. By utilizing a WMS, warehouse managers gain real-time visibility into all warehouse operations, enabling proactive decision-making. Data analysis capabilities within WMS provide valuable insights into operational performance, enabling warehouse managers to identify and address inefficiencies promptly and effectively.

Employing data analytics tools to monitor warehouse performance and identify areas for improvement is also critical. Real-time data analysis tools enable warehouse managers to identify patterns, trends, and anomalies, allowing for proactive interventions to address issues before they escalate. This approach not only reduces operational costs but also enhances the overall efficiency and productivity of the warehouse.

Employing mobile devices and scanners for real-time inventory updates and order tracking is a powerful method. These tools enhance accuracy and reduce errors, further optimizing the warehouse processes. The combination of robust warehouse management systems (WMS), advanced analytics, and mobile technology creates a dynamic and responsive warehouse environment.

Furthermore, utilizing advanced technologies like machine learning (ML) and artificial intelligence (AI) can help optimize warehouse operations by predicting demand, optimizing stock levels, and enhancing safety measures. These advancements, while complex, offer substantial benefits by making predictions about future demand, optimizing stock levels, and enhancing safety measures in the warehouse.

Future Trends and Challenges in Robotic Container Unloading

Autonomous Navigation and Control Systems

Advancements in artificial intelligence (AI) and machine learning (ML) are driving the development of autonomous navigation systems for robots involved in container unloading. These systems enable robots to perceive and interpret their surroundings dynamically, adapting to various environmental factors such as changing weather conditions, uneven surfaces, and cluttered spaces. This adaptive capability is crucial for reliable and efficient operation in real-world port environments. Furthermore, these systems are being designed to learn from past experiences, continuously improving their performance and minimizing errors over time. This evolution is essential for the long-term viability and scalability of robotic container unloading solutions.

The development of robust control systems is paramount for precise and safe manipulation of containers. These systems must account for the dynamic forces encountered during the lifting, movement, and placement of heavy containers. This involves sophisticated algorithms that predict and compensate for potential disturbances, ensuring that the robots maintain stability and prevent accidents. The integration of sensors and actuators, with real-time feedback loops, contributes significantly to the accuracy and efficiency of the entire process.

Integration with Existing Port Infrastructure

Successful implementation of robotic container unloading systems hinges on seamless integration with existing port infrastructure. This necessitates modifications and adaptations to existing workflows, including the development of standardized communication protocols and interfaces. Port operators must consider the compatibility of robotic systems with existing cranes, conveyor belts, and other equipment. This integration is essential for minimizing disruptions to existing operations and maximizing the overall efficiency of the port.

Furthermore, the integration must address potential security concerns. Robotic systems must be designed with robust security measures, including access controls and data encryption, to prevent unauthorized access and maintain the integrity of sensitive port data. The integration process requires careful planning, collaboration between port authorities and robotic system developers, and adherence to established safety protocols.

Optimization of Workflow and Logistics

Optimizing the workflow for robotic container unloading is crucial for maximizing throughput and minimizing operational costs. This involves developing algorithms and strategies that can analyze real-time data from various sources, such as container tracking systems and vessel schedules, to determine the most efficient sequence for unloading containers. This data-driven approach ensures that robots are deployed to the most optimal tasks at the most optimal times, reducing idle time and increasing overall productivity.

Effective integration with logistics management systems is another key aspect of optimization. This allows for real-time tracking of container movement, automated updates on delivery schedules, and proactive adjustments to unloading plans based on changing circumstances. This comprehensive approach to logistics management significantly enhances the overall efficiency and reliability of the entire process, ultimately improving customer satisfaction.

Safety and Maintenance Considerations

Ensuring the safety of both human workers and robotic systems is paramount in the implementation of robotic container unloading systems. Safety protocols must be integrated into the design and operation of the robots, including redundant safety mechanisms and emergency shut-off procedures. This is essential to mitigate potential risks during operation and minimize the potential for accidents. Furthermore, robust maintenance protocols are crucial for the long-term reliability and performance of robotic systems. Predictive maintenance strategies, leveraging sensor data and AI algorithms, can identify potential issues before they lead to breakdowns, minimizing downtime and maximizing operational efficiency.

The development of standardized maintenance procedures, training programs for technicians, and readily available spare parts will be essential for the sustained operation of these systems. This proactive approach to maintenance ensures the continued smooth functioning of the robotic systems and the overall efficiency of the port operations.

Read more about Robotics for automated container unloading

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit