AI for automated supplier onboarding and compliance

Improving Efficiency and Reducing Costs through Automation

Implementing AI-Powered Supply Chain Optimization

Artificial intelligence (AI) offers a powerful toolkit for optimizing supply chains. AI algorithms can analyze vast amounts of data, identifying patterns and anomalies that human analysts might miss. This allows for proactive adjustments to inventory levels, predicting potential disruptions, and streamlining logistics. By automating these processes, businesses can significantly reduce operational costs and improve overall efficiency.

This optimization goes beyond simple forecasting. AI can integrate with various supply chain elements, from demand forecasting to warehouse management. Real-time insights into market trends, supplier performance, and transportation conditions enable swift adaptation to changing circumstances, minimizing delays and ensuring product availability.

Predictive Maintenance for Equipment

AI-driven predictive maintenance can dramatically reduce downtime and maintenance costs. By analyzing sensor data from equipment, AI can identify subtle patterns indicative of potential failures. This allows for proactive maintenance interventions, preventing costly breakdowns and ensuring equipment operates at peak performance. The result is a significant reduction in unplanned downtime, leading to substantial cost savings.

Beyond just identifying potential failures, AI can also optimize maintenance schedules. Predicting when maintenance is needed allows for scheduling work during periods of low demand, reducing operational disruption and minimizing lost production time.

Automated Inventory Management

AI algorithms excel at managing inventory levels. By analyzing historical sales data, market trends, and external factors, AI systems can predict future demand with greater accuracy than traditional methods. This allows for optimized inventory levels, reducing storage costs and minimizing the risk of stockouts or overstocking. This is a critical aspect of supply chain efficiency, directly impacting profitability.

Enhanced Supplier Relationship Management

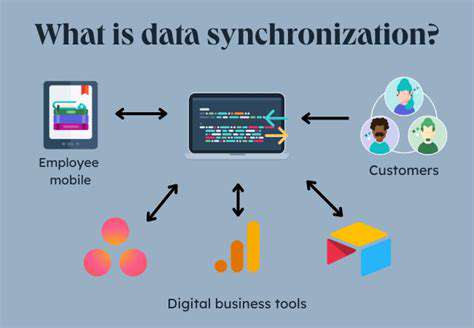

AI can improve supplier relationship management by automating communication and data exchange. This not only reduces administrative overhead but also fosters stronger relationships built on trust and transparency. AI can identify potential risks in supplier performance, allowing companies to proactively address issues and maintain a reliable supply chain. Automating these interactions reduces the manual effort required, freeing up human resources for more strategic tasks.

Optimizing Transportation and Logistics

AI algorithms can optimize transportation routes and schedules, minimizing fuel consumption and delivery times. By considering real-time traffic conditions, weather patterns, and delivery requirements, AI can suggest the most efficient routes, reducing transportation costs and improving delivery reliability. This automation significantly improves the speed and efficiency of the entire supply chain process.

Improved Demand Forecasting and Planning

AI excels at analyzing complex data sets to predict future demand with remarkable accuracy. This allows for more precise inventory planning, optimized production schedules, and better resource allocation across the supply chain. The insights gained enable businesses to anticipate changes in demand, adjusting production and inventory levels in advance, minimizing the risk of stockouts or excess inventory. This proactive approach to demand forecasting is crucial for reducing waste and improving overall profitability.

Real-time Monitoring and Control

AI enables real-time monitoring and control of the entire supply chain. By continuously tracking various metrics, AI can identify and address potential issues before they escalate, ensuring smooth operations and minimizing disruptions. This constant oversight allows for immediate adjustments to inventory levels, production schedules, and transportation routes, keeping the entire supply chain running smoothly and efficiently. This continuous, real-time feedback loop is a hallmark of AI-powered supply chain management.

Read more about AI for automated supplier onboarding and compliance

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit