Digital Twin for Optimized Transportation Logistics

Introduction to Digital Twins in Transportation

What are Digital Twins in Transportation?

Digital twins in transportation represent a virtual replica of a physical asset or system, such as a vehicle, a road network, or a port facility. This virtual representation is meticulously modeled to reflect the real-world counterpart's characteristics, behavior, and performance. Crucially, data from the physical system feeds the digital twin, allowing for real-time monitoring and simulation of various scenarios, thereby enabling predictive maintenance, optimized operations, and enhanced safety measures. This allows for a comprehensive understanding of the system's performance and potential issues before they manifest in the physical world.

Essentially, a digital twin acts as a dynamic, interactive simulation platform. It empowers stakeholders across the transportation sector to make data-driven decisions, optimize resource allocation, and anticipate potential disruptions. This proactive approach to problem-solving is a key advantage compared to traditional reactive methods of dealing with issues.

Key Benefits of Implementing Digital Twins

The implementation of digital twins in transportation offers a plethora of advantages. One significant benefit is the ability to conduct extensive simulations of different operational scenarios without incurring the costs and risks associated with physical testing. This allows for experimentation with various strategies and configurations to identify the most optimal solutions for improving efficiency and reducing operational costs.

Predictive maintenance is another critical application. By continuously monitoring the digital twin, potential failures in vehicles, infrastructure, or equipment can be identified well in advance. This allows for proactive maintenance schedules, minimizing downtime and maximizing operational efficiency. Real-time performance monitoring is also possible, enabling immediate adjustments and interventions to address issues before they escalate.

Applications Across the Transportation Spectrum

Digital twins are not limited to a single application within the transportation sector. They can be applied to various aspects, including vehicle design and optimization, traffic flow management, port operations, and logistics. For instance, a digital twin of a vehicle can be used to simulate various driving conditions and optimize its design for enhanced fuel efficiency and safety.

Similarly, a digital twin of a city's road network can help in traffic flow management, predicting congestion, and optimizing traffic signal timing. This allows for improved response to real-time traffic conditions and enhanced public transportation efficiency. Furthermore, digital twins can be used to simulate and optimize logistics processes in supply chains, enhancing delivery times, and reducing costs.

Challenges and Future Directions

Despite the numerous benefits, implementing digital twins in transportation also presents some challenges. One primary concern is the sheer volume of data required to create and maintain an accurate and comprehensive digital twin. Collecting, processing, and integrating this data from various sources can be complex and costly.

Another challenge lies in the need for skilled personnel to develop, manage, and interpret the data generated by the digital twins. Furthermore, ensuring the security and privacy of the sensitive data used in these systems is crucial. Looking ahead, advancements in data analytics, cloud computing, and artificial intelligence are expected to further enhance the capabilities of digital twins in transportation, paving the way for even more sophisticated applications and optimized solutions in the future.

Predictive Maintenance and Enhanced Vehicle Performance

Predictive Maintenance Strategies

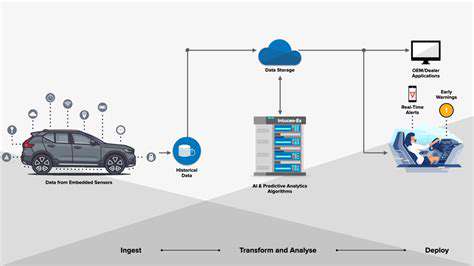

Predictive maintenance is a proactive approach to maintenance that focuses on anticipating equipment failures before they occur. This method leverages data analysis and machine learning algorithms to identify patterns and anomalies in equipment performance data, allowing for timely intervention and minimizing costly downtime. By monitoring various parameters like vibration, temperature, and pressure, predictive maintenance systems can detect early warning signs of potential failures, enabling maintenance teams to schedule repairs or replacements in advance. This proactive approach significantly reduces unplanned downtime and enhances overall equipment effectiveness.

A key aspect of predictive maintenance is the collection and analysis of vast amounts of data. This data is often gathered from various sources, including sensors embedded in equipment, operational logs, and historical maintenance records. Sophisticated algorithms then analyze this data to identify trends, anomalies, and patterns that indicate potential failures. This data-driven approach allows for more informed and targeted maintenance strategies, resulting in optimized resource allocation and significant cost savings. The accurate prediction of equipment failures allows for the scheduling of maintenance activities during planned downtime, further minimizing disruption to production schedules.

Enhancing Equipment Reliability

Implementing predictive maintenance strategies directly contributes to enhanced equipment reliability. By proactively addressing potential failures, the risk of unexpected breakdowns is significantly reduced. This proactive approach minimizes the occurrence of costly unplanned downtime, ultimately leading to increased operational efficiency and productivity. Predictive maintenance solutions often provide detailed insights into equipment performance, enabling maintenance teams to make data-driven decisions regarding maintenance schedules and resource allocation.

The improved reliability of equipment translates into fewer unscheduled breakdowns and a more consistent production output. This consistency is crucial for maintaining production targets and meeting customer demands. By preventing equipment failures before they occur, predictive maintenance systems safeguard critical equipment and processes, contributing to a higher level of operational stability.

Improved Operational Efficiency

The implementation of predictive maintenance strategies fosters a significant improvement in operational efficiency. By minimizing unplanned downtime and optimizing maintenance schedules, businesses can significantly reduce their maintenance costs and improve overall operational efficiency. Reduced downtime directly translates to increased production output, leading to higher profitability and improved return on investment.

Predictive maintenance systems also allow for optimized resource allocation. By pinpointing equipment that needs attention, maintenance teams can allocate their resources more effectively. This efficient allocation of resources helps minimize the impact of unexpected breakdowns and ensures that maintenance efforts are focused on the most critical equipment, which ultimately strengthens the overall reliability and efficiency of the entire operation. By optimizing maintenance schedules and reducing the risk of unplanned downtime, predictive maintenance significantly contributes to operational excellence.

Improving Warehouse Management and Inventory Control

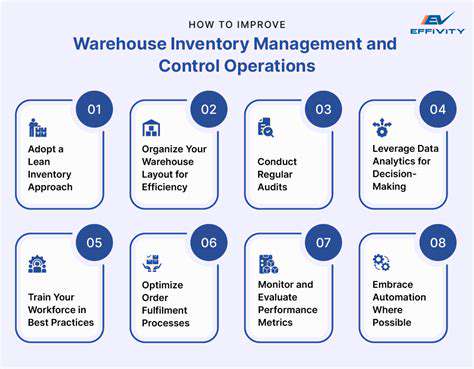

Optimizing Receiving Processes

A well-structured receiving process is crucial for efficient warehouse operations. This involves clear procedures for verifying incoming goods against purchase orders, ensuring accurate documentation, and promptly storing items in designated locations. A streamlined receiving process minimizes delays and errors, improving overall warehouse efficiency and reducing potential losses due to discrepancies.

Implementing barcode scanning or RFID technology during the receiving stage can significantly speed up the process. This automated approach reduces manual data entry errors and allows for real-time tracking of inventory, enabling managers to make informed decisions about stock levels and potential shortages.

Streamlining Storage Strategies

Effective storage strategies are vital for maximizing warehouse space and ensuring easy access to inventory. Implementing a well-organized system, such as using a designated location for each product type, is essential to prevent clutter and reduce search time. Proper labeling and organization are essential for maintaining inventory control and order fulfillment accuracy.

Utilizing warehouse management systems (WMS) can help optimize storage space by providing real-time data on inventory location. This data allows for more efficient storage layouts and better allocation of space, minimizing wasted storage areas.

Improving Order Picking Accuracy

Accurate order picking directly impacts customer satisfaction and order fulfillment times. Well-defined picking procedures, clear labeling, and proper training for picking personnel are paramount in minimizing errors. Implementing a picking sequence that optimizes the movement of employees and minimizes travel time is crucial for efficiency.

Implementing Efficient Shipping Processes

A smooth shipping process is essential for timely delivery and customer satisfaction. Effective communication between the warehouse and shipping department is critical to avoid delays and ensure accurate shipping information. Implementing efficient packing procedures that minimize damage during transit and ensure proper labeling are key aspects of this stage.

Prioritizing the use of appropriate packaging materials and ensuring that orders are shipped in a timely manner can improve customer satisfaction and brand reputation.

Utilizing Inventory Management Systems

Comprehensive inventory management systems are essential for tracking stock levels, predicting demand, and minimizing waste. These systems offer real-time visibility into inventory, enabling proactive adjustments to stock levels and minimizing the risk of stockouts or overstocking.

Real-time data visibility enables better forecasting and decision-making regarding inventory replenishment. Utilizing historical data and sales trends allows for more accurate predictions, reducing the need for guesswork and optimizing inventory levels to meet customer demand.

Enhancing Safety and Security Measures

Warehouse safety is paramount for employee well-being and minimizing accidents. Implementing clear safety protocols, providing proper training, and maintaining a safe working environment are crucial to preventing injuries and ensuring smooth operations.

Implementing security measures to prevent theft and damage to inventory, such as proper access controls and surveillance systems, is also essential to protect the warehouse's assets and maintain operational efficiency.

Enhanced Safety and Risk Management in Logistics

Improving Operational Efficiency

Implementing a digital twin allows for proactive identification and mitigation of potential risks throughout the entire logistics process. By simulating real-world scenarios and analyzing various operational parameters, such as traffic flow, weather patterns, and equipment performance, potential bottlenecks and disruptions can be predicted and addressed before they impact the delivery schedule. This proactive approach minimizes costly delays and ensures smooth, efficient operations, ultimately enhancing the overall performance of the logistics network.

Predictive Maintenance and Proactive Repairs

Digital twins provide a virtual replica of physical assets, enabling sophisticated predictive maintenance strategies. By monitoring the real-time performance data of vehicles, equipment, and infrastructure, the system can anticipate potential equipment failures, enabling proactive maintenance interventions. This approach minimizes unplanned downtime, reduces repair costs, and ensures the optimal performance and longevity of critical assets. This translates directly into a more reliable and efficient logistics operation.

Real-time tracking of asset health allows for optimized maintenance schedules, minimizing unnecessary interventions and maximizing operational uptime. This continuous monitoring and predictive analysis significantly reduces the risk of unexpected breakdowns, ensuring consistent and reliable delivery services.

Enhanced Safety Measures and Risk Assessment

A critical aspect of enhanced safety in logistics is the ability to model and simulate potentially hazardous situations. The digital twin allows for the creation of virtual environments that can be used to test the effectiveness of safety protocols and emergency response plans, enabling companies to identify and address potential safety risks before they occur. By simulating various scenarios, such as accidents, natural disasters, or security threats, businesses can proactively implement safety measures and train personnel on appropriate responses, leading to a safer and more resilient logistics system.

Optimizing Resource Allocation and Demand Forecasting

Using data from the digital twin, logistics companies can more accurately forecast demand and optimize resource allocation. By simulating various scenarios and considering factors such as fluctuating demand, seasonal variations, and unforeseen events, the system can provide insights into optimal resource deployment, including the allocation of vehicles, personnel, and storage space. This leads to a more efficient use of resources and minimizes waste, ultimately reducing operational costs.

Improved Collaboration and Communication

A digital twin fosters seamless collaboration and communication among all stakeholders involved in the logistics process. By providing a centralized platform for data visualization and communication, the digital twin facilitates real-time information sharing among drivers, warehouse staff, dispatchers, and other relevant personnel. This improved communication and collaboration results in quicker response times to unexpected events, reduced miscommunication, and improved overall coordination, ultimately leading to a more efficient and streamlined supply chain.

Read more about Digital Twin for Optimized Transportation Logistics

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit