Computer vision: Automating quality control and inspection

Automated Visual Inspection Systems: A Comprehensive Overview

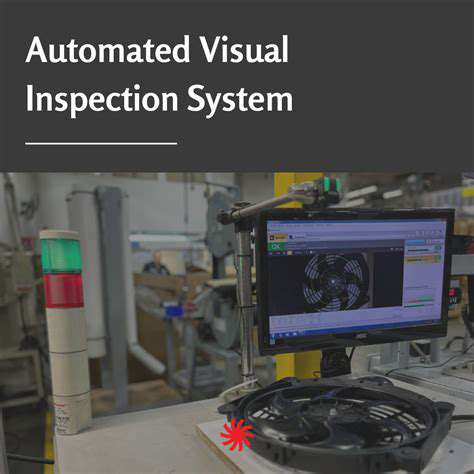

Automated visual inspection systems are rapidly transforming various industries, from manufacturing and quality control to healthcare and scientific research. These systems leverage computer vision and image processing techniques to analyze visual data, identifying defects, anomalies, and patterns that might be missed by the human eye. This automation significantly improves efficiency and accuracy in inspection processes, leading to cost savings and higher product quality.

The core functionality of these systems revolves around capturing images or videos, processing them using algorithms, and then extracting meaningful information. This process often involves tasks like object detection, pattern recognition, and image segmentation. Different types of defects can be identified, including scratches, dents, and other structural imperfections.

Key Benefits of Automated Visual Inspection

One of the primary advantages of automated visual inspection is the significant reduction in inspection time. This translates directly into higher throughput and faster production cycles, which are critical for businesses operating in competitive markets. Automated systems can also process a much larger volume of data in a shorter period than human inspectors, leading to greater overall efficiency

Furthermore, automated systems offer consistent and reliable results, minimizing the risk of human error. This consistency ensures that quality standards are maintained throughout the production process, ultimately improving product quality and customer satisfaction.

Technological Advancements in Image Processing

Recent advancements in deep learning and artificial intelligence have significantly improved the performance of automated visual inspection systems. Deep learning models, especially convolutional neural networks (CNNs), are highly effective at recognizing complex patterns and features in images, enabling the detection of subtle defects that might be missed by traditional methods. The accuracy and speed of these systems are constantly improving, allowing for more rapid and reliable defect identification.

These advancements are driving a shift towards more sophisticated and intelligent inspection systems capable of handling a wider variety of tasks and data types. This evolution is leading to more sophisticated and robust automated inspection systems that can accurately identify a wider variety of defects in a wider variety of materials and products.

Applications Across Industries

Automated visual inspection systems are employed in a diverse range of industries. In manufacturing, they are crucial for inspecting components, ensuring quality control, and preventing costly rework. In the automotive industry, these systems can quickly and accurately identify defects in paint jobs or structural components.

Beyond manufacturing, applications extend to healthcare, where these systems can analyze medical images for potential anomalies. In agriculture, they can assist in crop monitoring and quality assessment.

Challenges and Future Trends

While the benefits of automated visual inspection are substantial, certain challenges remain. These include the need for significant upfront investment in hardware and software, as well as the potential for system failures or malfunctions. The training and maintenance of these complex systems require specialized expertise, leading to additional costs.

Future trends point towards greater integration of these systems with other technologies, such as machine learning and the Internet of Things. This integration will enable more sophisticated data analysis and real-time feedback, ultimately leading to even more efficient and effective inspection processes.

Beyond Basic Inspection: Advanced Applications

Beyond Visual Scrutiny: Deep Dive into Inspection Techniques

Advanced inspection methods move beyond the basic visual examination, delving deeper into the intricacies of a product or system to identify potential defects or anomalies. This deeper level of scrutiny often involves specialized equipment and highly trained personnel, ensuring a comprehensive evaluation of the entire structure, component, or process. Thoroughness is paramount in advanced inspection, ensuring that even subtle flaws are detected and addressed promptly.

These methods often include sophisticated imaging techniques, such as X-ray, ultrasonic, or thermal imaging, providing detailed internal views of the object under inspection. This allows for the identification of hidden defects or inconsistencies that might not be visible to the naked eye. Advanced inspection not only saves time and resources in the long run but can also prevent costly failures or recalls.

Employing Specialized Tools and Technologies

A critical aspect of advanced inspection is the utilization of specialized tools and technologies. These tools often provide detailed data, which is then analyzed to identify potential issues. High-precision measuring instruments, for example, can detect minute deviations from specifications. Advanced inspection also leverages sophisticated software for data analysis, allowing for precise measurements and pattern recognition in large datasets. This advanced analysis helps to predict potential problems and improve overall product quality.

Beyond the tools themselves, the training and expertise of the personnel operating them are essential. Operators need to understand the specific capabilities and limitations of each tool, as well as how to interpret the data generated. This expertise ensures accurate results and allows for the proper identification and classification of any detected anomalies. This level of expertise is crucial in ensuring that advanced inspection methods are applied correctly and yield reliable results.

Data Analysis and Interpretation for Improved Outcomes

A significant part of advanced inspection is the thorough analysis and interpretation of the data collected. This involves using statistical methods and sophisticated algorithms to identify patterns, trends, and anomalies within the data. The collected data from various inspection methods needs to be integrated and correlated to form a comprehensive understanding of the inspected object or system.

Furthermore, data interpretation needs to be linked to the specific requirements and standards of the inspected product or process. This allows for objective comparisons and the identification of deviations from acceptable parameters. By carefully analyzing the collected data, inspectors can identify potential weaknesses or areas of improvement, leading to better decision-making and optimized processes.

Finally, the results of advanced inspection should be documented and reported meticulously. This ensures transparency and traceability, allowing for continuous improvement and the ability to refer back to past inspections for future reference.

Effective data analysis often leads to a deeper understanding of the inspected item, revealing potential flaws or areas for improvement. This often leads to a more proactive approach to quality control and maintenance.

Read more about Computer vision: Automating quality control and inspection

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit