Visibility for Global Supply Chains: Navigating Complexity

Building Resilient Supply Chains Through Visibility

Understanding the Importance of Visibility

Supply chain visibility is more than just knowing where your goods are at any given moment. It's about gaining a comprehensive understanding of the entire journey, from raw material sourcing to final delivery. This encompasses tracking not only physical movement but also factors like production capacity, potential delays, and even changes in weather patterns that could impact transportation. With visibility, businesses can proactively address potential disruptions, optimize resource allocation, and ultimately reduce costs and improve responsiveness to market fluctuations. A clear picture of your supply chain is crucial for making informed decisions and building a more resilient network.

Effective visibility allows businesses to anticipate and react to potential problems before they escalate into major crises. By monitoring key performance indicators (KPIs) across the entire supply chain, companies can identify bottlenecks, inefficiencies, and vulnerabilities. This proactive approach enables them to implement corrective measures and ensure the smooth and uninterrupted flow of goods. Real-time information empowers businesses to make swift adjustments to their strategies, ensuring continued operations even in challenging circumstances.

Leveraging Technology for Enhanced Visibility

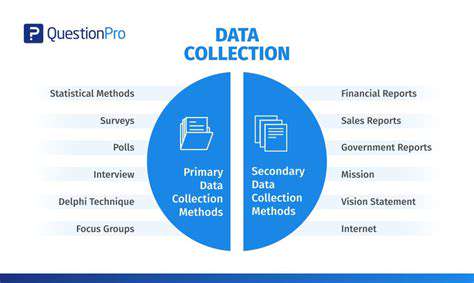

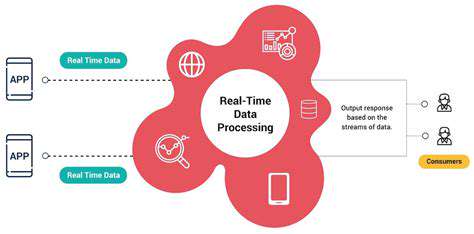

Modern technology plays a pivotal role in achieving robust supply chain visibility. Advanced tracking systems, coupled with robust data analytics platforms, provide a 360-degree view of the entire supply chain. This real-time data allows companies to monitor every stage of the process, from raw material extraction to the final customer delivery. The integration of various technologies, including GPS tracking, RFID tags, and blockchain, creates a seamless and interconnected system for data collection and analysis, empowering businesses to make informed decisions based on accurate and up-to-date information.

Implementing these technologies can lead to significant improvements in efficiency and cost savings. For example, by tracking shipments in real-time, businesses can identify potential delays and take corrective actions, such as rerouting shipments or deploying additional resources. Real-time data insights also enable more accurate inventory management, reducing storage costs and minimizing stockouts. Furthermore, advanced analytics can identify patterns and predict future disruptions, allowing for proactive mitigation strategies.

Building a Resilient Supply Chain through Collaboration

Building a truly resilient supply chain requires more than just technological advancements. Strong collaboration between various stakeholders, including suppliers, manufacturers, distributors, and retailers, is essential for shared visibility and proactive problem-solving. Open communication channels and data sharing agreements between partners allow for a comprehensive view of the entire supply chain, enabling faster responses to disruptions and minimizing their impact. This collaborative approach fosters a shared sense of responsibility and collective problem-solving, strengthening the entire network and ensuring greater stability.

Promoting transparency and shared responsibility among partners is key to building a resilient supply chain. By fostering open communication and data sharing, businesses can work together to anticipate and address potential issues. This collaborative environment allows for a more holistic understanding of the entire supply chain and empowers all stakeholders to contribute to its resilience. Ultimately, this collaborative spirit can lead to a more adaptable and reliable supply chain that can withstand unforeseen challenges.

Read more about Visibility for Global Supply Chains: Navigating Complexity

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit