The Impact of Digital Twin Technology on Supply Chain Decision Making

Predictive Maintenance and Proactive Risk Management

Predictive Maintenance Strategies

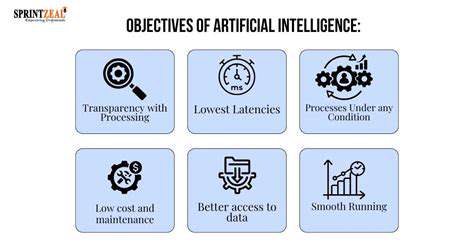

Predictive maintenance (PdM) is a proactive approach to equipment maintenance that focuses on anticipating potential failures before they occur. Instead of relying on reactive maintenance, which addresses problems after they arise, PdM leverages data analysis and machine learning to identify patterns and anomalies that signal impending issues. This allows organizations to schedule maintenance activities at optimal times, minimizing downtime and maximizing equipment lifespan. Predictive maintenance can significantly reduce maintenance costs and improve overall operational efficiency by preventing costly breakdowns.

Various data sources, such as sensor readings, vibration data, and operational logs, are crucial for predictive maintenance. These data points are collected and analyzed to identify trends and predict potential failures. By understanding the relationship between these data points and equipment performance, PdM systems can provide early warnings of impending problems, allowing for preemptive maintenance actions. This proactive approach contributes to a more reliable and sustainable operational environment.

Data Analysis Techniques

Data analysis plays a vital role in predictive maintenance. Sophisticated algorithms and machine learning models are employed to analyze large datasets of operational data, identifying patterns and anomalies that indicate potential equipment failures. This analysis can range from simple statistical methods to complex machine learning techniques, such as neural networks and support vector machines. Through careful analysis, predictive maintenance systems can identify subtle indicators of wear and tear, allowing for timely interventions before catastrophic failures occur.

Statistical process control (SPC) and time series analysis are common methods used to identify trends and anomalies in equipment performance data. These techniques can help pinpoint deviations from expected behavior, providing early warning signs of potential issues. Advanced methods, such as machine learning models, can identify more complex relationships and patterns within the data, enabling more accurate predictions of future equipment performance.

Benefits of Predictive Maintenance

The benefits of implementing predictive maintenance strategies are substantial. Reduced downtime is a key advantage, as maintenance activities can be scheduled proactively, minimizing disruptions to production schedules. Improved equipment reliability is another significant benefit, as PdM systems can identify and address potential issues before they escalate to major failures. Lower maintenance costs are also a result, as preventative measures are taken before breakdowns occur, reducing the need for costly repairs and replacements.

Predictive maintenance contributes to a safer working environment by reducing the risk of unexpected equipment failures. By proactively addressing potential issues, organizations can minimize the risk of accidents and injuries. Furthermore, predictive maintenance can improve overall operational efficiency and profitability by optimizing maintenance schedules and reducing downtime.

Implementation Considerations

Implementing a predictive maintenance program requires careful planning and execution. Data collection and management are crucial aspects, as the accuracy of predictions depends on the quality and completeness of the data. Establishing a robust data infrastructure for collecting, storing, and analyzing data is essential for effective PdM systems. Integrating existing maintenance systems and processes with the new PdM system is also important for a smooth transition and effective data flow.

Choosing the right algorithms and machine learning models is critical for accurate predictions. Training and upskilling maintenance personnel on the new system is essential for successful adoption and implementation. Continuous monitoring and evaluation of the system performance are vital for identifying areas for improvement and optimizing the predictive maintenance strategy.

Cost Reduction and Increased Profitability

Cost Reduction Strategies

Implementing effective cost reduction strategies is crucial for any organization aiming to improve profitability. These strategies encompass a wide range of approaches, from streamlining operational processes to negotiating better deals with suppliers. Identifying and eliminating unnecessary expenses is paramount to achieving significant cost savings. A thorough analysis of current expenditures is essential to pinpoint areas where reductions can be made without compromising quality or service.

One key strategy involves optimizing inventory management. By implementing techniques such as just-in-time inventory, businesses can minimize storage costs and reduce the risk of obsolescence. This approach ensures that materials are available when needed, preventing costly overstocking and ensuring materials are not sitting idle. Furthermore, implementing efficient supply chain management practices can further reduce costs by optimizing transportation and logistics.

Process Optimization for Efficiency

Streamlining internal processes is another critical aspect of cost reduction. Analyzing current workflows and identifying bottlenecks can lead to significant improvements in efficiency. Employing automation tools and technologies can significantly reduce manual labor costs and improve productivity. This approach can also lead to reduced errors, thereby minimizing rework and associated costs.

Implementing lean manufacturing principles can optimize production processes, reducing waste and improving efficiency. This involves eliminating non-value-added activities and maximizing resource utilization. By focusing on continuous improvement and eliminating waste, organizations can significantly reduce costs and improve overall productivity.

Revenue Enhancement Strategies

Enhancing revenue streams is just as important as reducing costs. Focusing on upselling and cross-selling opportunities can significantly increase revenue without increasing expenses. Training sales staff on these techniques can lead to a noticeable increase in revenue generation.

Implementing strategies to attract more customers, such as targeted marketing campaigns and improved customer service, can also boost revenue. By understanding customer needs and preferences, businesses can tailor their offerings to meet those needs and create more loyal customers. This approach not only increases sales but also fosters long-term relationships, leading to sustained revenue growth.

Profitability Analysis and Reporting

Regularly analyzing profitability is essential to track progress and identify areas for improvement. A comprehensive understanding of cost structures and revenue streams is key to assessing profitability. Implementing robust financial reporting systems can provide clear insights into the financial health of the business. This allows for informed decision-making and the implementation of strategies to improve profitability.

Analyzing cost variances and identifying trends is critical to understanding the root causes of profitability fluctuations. Using this data, businesses can make informed decisions regarding pricing strategies and cost-cutting measures. Understanding the drivers of profitability is essential for long-term success.

Read more about The Impact of Digital Twin Technology on Supply Chain Decision Making

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit