Supply Chain Visibility for Enhanced Quality Control

Leveraging Technology for Transparency and Accountability

Improving Supply Chain Visibility through Data Analytics

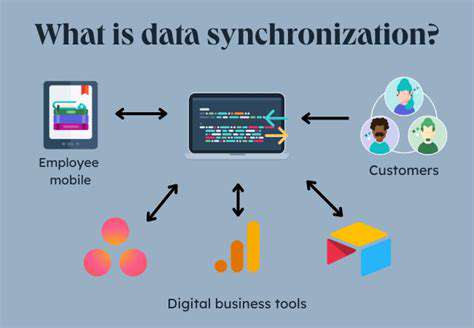

Data analytics plays a crucial role in enhancing supply chain visibility by providing real-time insights into various stages of the process. By analyzing data from diverse sources, such as sensors, RFID tags, and logistics platforms, businesses can identify potential bottlenecks, predict disruptions, and optimize resource allocation. This detailed understanding of the movement of goods and materials empowers companies to make proactive decisions, reducing delays and improving overall efficiency. The ability to track inventory, monitor delivery times, and identify potential risks early on significantly contributes to building a more transparent and accountable supply chain.

Furthermore, data analytics enables businesses to identify trends and patterns that may indicate future issues. For example, analyzing historical data on delivery times, weather patterns, or even supplier performance can help predict potential delays and allow for proactive measures to mitigate risks. This predictive capability is vital for maintaining a stable and responsive supply chain, ensuring on-time delivery and minimizing disruptions.

Implementing Blockchain Technology for Enhanced Traceability

Blockchain technology offers a secure and transparent way to track goods throughout the supply chain. By recording every transaction on an immutable ledger, businesses can build trust and accountability with partners and customers. This enhanced traceability allows stakeholders to identify the origin of products, verify authenticity, and monitor the entire journey from origin to consumer.

The decentralized nature of blockchain eliminates the need for intermediaries, streamlining processes and reducing costs. This technology fosters transparency and accountability by making all transactions auditable and verifiable, significantly enhancing the overall reliability and trustworthiness of the supply chain.

Utilizing IoT Devices for Real-Time Tracking and Monitoring

Internet of Things (IoT) devices, such as sensors and RFID tags, can be strategically placed throughout the supply chain to provide real-time tracking and monitoring of goods. These devices collect data on location, temperature, and other critical factors, enabling companies to monitor the condition of goods and identify potential issues early on. This continuous monitoring allows for proactive adjustments to prevent damage or spoilage, leading to improved product quality and reduced waste.

By providing real-time data on the location and condition of goods, IoT technology empowers businesses to optimize logistics and delivery routes. This real-time visibility allows for faster response times to unexpected events, minimizing potential disruptions and ensuring timely delivery. The data collected from these devices can also be used to refine operational processes and improve overall efficiency within the supply chain.

Establishing Clear Communication Channels and Reporting Mechanisms

Effective communication and robust reporting mechanisms are essential for maintaining transparency and accountability within a supply chain. Establishing clear communication channels among all stakeholders, including suppliers, manufacturers, distributors, and retailers, ensures that information flows smoothly and efficiently. This enables prompt responses to issues and facilitates collaboration in mitigating potential risks.

Implementing regular reporting mechanisms, such as dashboards and progress updates, provides stakeholders with a clear overview of the supply chain's performance. Regular reporting allows for early detection of deviations from planned activities and facilitates timely corrective actions. These mechanisms not only enhance accountability but also build trust and transparency throughout the entire supply chain.

Predictive Analytics for Anticipating Quality Challenges

Predictive Modeling Techniques

Predictive analytics leverages various modeling techniques to forecast future outcomes. These techniques range from simple linear regression to complex machine learning algorithms like support vector machines and neural networks. Choosing the appropriate technique depends heavily on the nature of the data and the desired level of accuracy. Understanding the strengths and limitations of each method is crucial for achieving reliable predictions.

Linear regression, for example, is effective when exploring the relationship between a continuous dependent variable and one or more independent variables. However, its application is limited when dealing with non-linear relationships or complex datasets. More sophisticated methods like decision trees or random forests offer greater flexibility for handling diverse data structures and uncovering intricate patterns.

Data Preparation and Feature Engineering

A critical aspect of successful predictive modeling is the meticulous preparation of the data. This often involves cleaning, transforming, and potentially engineering new features from existing ones. Missing values need to be addressed, outliers identified and handled appropriately, and data scaled to prevent features with larger values from dominating the model. Thorough data preparation directly impacts the accuracy and reliability of the predictive model.

Feature engineering plays a vital role in transforming raw data into a format suitable for the model. This might involve creating new variables based on existing ones, converting categorical data into numerical representations, or extracting relevant information from textual data. These steps are often tailored to the specific characteristics of the dataset and the intended predictive outcome. Proper feature engineering is essential for achieving high predictive accuracy.

Model Evaluation and Validation

Evaluating the performance of a predictive model is paramount to ensure its effectiveness. Common metrics include accuracy, precision, recall, and F1-score. These metrics assess the model's ability to correctly classify instances and identify important distinctions. Careful consideration of these metrics helps in understanding the model's strengths and weaknesses and identifying potential areas for improvement. The process of evaluating a predictive model should be rigorous, focusing on a variety of aspects such as its bias and variance.

A crucial component of model validation involves using appropriate techniques like cross-validation to assess the model's generalizability. This method helps to prevent overfitting, a common issue where the model performs exceptionally well on training data but poorly on unseen data. Overfitting can result in inaccurate predictions and hinder the model's ability to effectively generalize to new situations.

Deployment and Monitoring

Once a predictive model is deemed satisfactory, it needs to be deployed into a production environment. This involves integrating the model into existing systems and establishing a process for continuous monitoring. Continuous monitoring ensures the model's performance remains consistent and accurate over time. It also identifies potential issues, like changes in the data or shifts in underlying relationships. This proactive approach helps maintain the model's effectiveness and relevance.

Monitoring involves tracking key performance indicators (KPIs) and retraining the model periodically. This ensures that the model remains aligned with the current data distribution and continues to accurately reflect the underlying patterns. Regular model updates and adjustments are essential for ongoing success.

Read more about Supply Chain Visibility for Enhanced Quality Control

Hot Recommendations

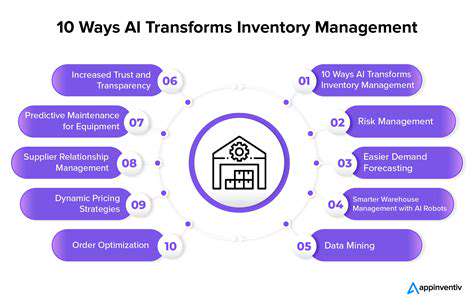

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

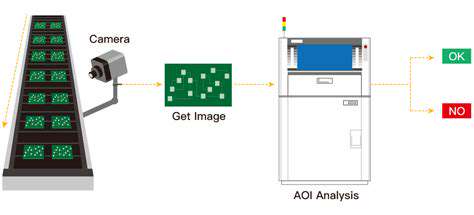

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit