Real World AI Case Studies in Supply Chain Success Stories

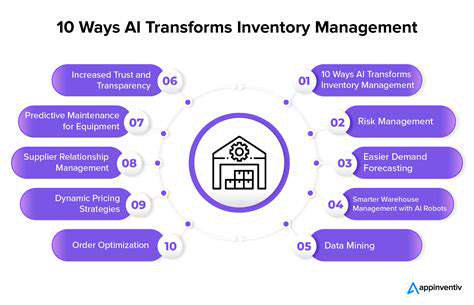

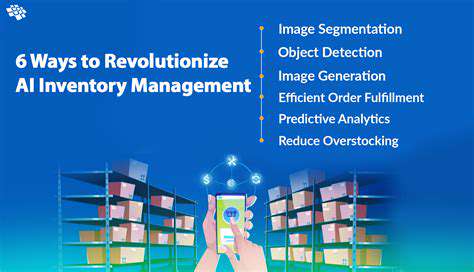

Revolutionizing Inventory Management with AI

Optimizing Stock Levels

Effective inventory management hinges on maintaining optimal stock levels. Having too much stock ties up valuable capital and increases storage costs, while insufficient stock can lead to lost sales and frustrated customers. A sophisticated system analyzes sales trends, lead times, and seasonal fluctuations to dynamically adjust stock levels, ensuring you always have the right amount of inventory on hand to meet demand without excess.

This dynamic approach to inventory management minimizes waste and maximizes profitability. By proactively adjusting stock levels, businesses can avoid costly overstocking and stockouts, thereby improving cash flow and customer satisfaction.

Real-time Tracking and Visibility

Real-time visibility into inventory levels is crucial for efficient operations. Modern inventory management systems offer detailed dashboards and reports that provide instant updates on stock locations, quantities, and movement. This real-time tracking allows for quick identification of potential issues, such as slow-moving items or stockouts, enabling proactive adjustments and preventing costly delays.

Automated Processes and Streamlined workflows

Automation plays a key role in streamlining inventory workflows. Automated systems reduce manual data entry errors, freeing up staff to focus on higher-value tasks. This automation also reduces the risk of human error, leading to a more accurate and efficient inventory management process.

By automating tasks like receiving, putaway, and picking, companies can significantly improve the speed and accuracy of their inventory processes, thus boosting overall operational efficiency.

Predictive Analytics for Future Planning

Utilizing predictive analytics allows businesses to anticipate future demands. By analyzing historical sales data, market trends, and external factors, companies can forecast future inventory needs and proactively adjust their stock levels. This predictive capability is crucial for optimizing resource allocation and minimizing potential stockouts.

Improved Supply Chain Collaboration

Enhanced inventory management often requires improved collaboration throughout the supply chain. Sharing real-time data and insights with suppliers and distributors allows for more accurate forecasting and better coordination of inventory movements. This improved visibility and communication leads to more efficient order fulfillment and reduced lead times.

Enhanced Customer Satisfaction

Efficient inventory management directly impacts customer satisfaction. By ensuring products are readily available when customers want them, businesses can maintain high levels of customer service. Minimizing stockouts and delays enhances customer experience, which fosters loyalty and positive word-of-mouth referrals.

Reduced Costs and Increased Profitability

Effective inventory management significantly reduces operational costs. By minimizing waste, avoiding stockouts, and optimizing storage space, companies can cut down on storage costs, carrying costs, and the costs associated with lost sales. This translates into improved profitability and enhanced financial performance.

Optimizing Transportation and Logistics with AI-Driven Route Planning

Improving Efficiency through AI-Powered Route Optimization

AI algorithms excel at analyzing vast datasets of real-time traffic conditions, weather patterns, and delivery constraints. This allows for the creation of dynamic routes that adapt to changing circumstances, minimizing delays and maximizing delivery speed. By continuously monitoring these factors, AI-driven systems can adjust routes in real-time, ensuring that deliveries are completed efficiently and on time, even when unexpected events disrupt the original schedule. This adaptive approach is a significant improvement over traditional, static route planning methods.

The ability of AI to predict potential road closures, accidents, or congestion enables proactive route adjustments. This predictive capability significantly reduces the risk of delays and ensures that deliveries are completed as planned. Furthermore, by incorporating data on delivery windows and customer preferences, AI systems can optimize routes to better meet these specific needs, leading to improved customer satisfaction.

Predictive Maintenance and Fleet Management

AI algorithms can analyze vehicle performance data, such as fuel consumption, engine diagnostics, and maintenance records, to predict potential maintenance needs. This predictive approach helps to schedule maintenance proactively, minimizing downtime and maximizing vehicle uptime. By analyzing historical data, AI can identify patterns and predict when a vehicle might require repair, allowing mechanics to address issues before they escalate, significantly reducing costly repairs and unexpected breakdowns.

AI-powered fleet management systems can also optimize fuel consumption by identifying driving patterns that waste fuel. This can lead to significant cost savings for transportation companies and a reduction in their environmental footprint. Furthermore, AI can track vehicle locations and manage driver performance, improving overall safety and efficiency.

Enhanced Customer Experience through Real-Time Tracking

AI-powered systems can provide real-time tracking of shipments, allowing customers to monitor the progress of their deliveries. This transparency and visibility significantly improve the customer experience by keeping them informed about the location and estimated arrival time of their packages. Real-time updates provide a sense of control and confidence, reducing anxiety about potential delays and enabling customers to plan accordingly.

The ability to provide accurate and up-to-the-minute tracking information builds trust and enhances customer satisfaction. By providing detailed information about the delivery process, AI systems empower customers to manage their expectations and anticipate the arrival of their shipments, leading to a more positive and efficient experience.

Optimizing Warehouse Operations

AI can be used to optimize warehouse operations by automating tasks like inventory management, order fulfillment, and picking and packing. By automating these processes, AI systems can significantly increase warehouse efficiency and reduce errors. AI can analyze vast amounts of data to identify trends and patterns in order fulfillment, enabling warehouse managers to optimize workflows and maximize throughput. This leads to faster order processing and improved delivery times.

AI algorithms can also predict demand fluctuations and optimize inventory levels. By understanding historical trends and current demand patterns, AI systems can help warehouse managers to maintain optimal stock levels, preventing overstocking and stockouts. This ensures that the right products are available when needed, minimizing delays and maximizing efficiency.

Reducing Costs and Improving Profitability

AI-driven route optimization and fleet management systems can lead to significant cost savings by reducing fuel consumption, minimizing downtime, and streamlining operations. By optimizing routes and schedules, AI systems can reduce transportation costs and improve delivery times, making the entire logistics process more efficient. This efficiency translates directly into increased profitability for transportation and logistics companies.

AI-powered systems can also identify areas for process improvement and cost reduction, enabling companies to streamline their operations and achieve greater efficiency. By analyzing vast datasets of operational data, AI systems can reveal hidden inefficiencies and suggest solutions, leading to significant cost savings and improved profitability.

Addressing Sustainability Concerns

AI can play a crucial role in promoting sustainability in transportation and logistics. By optimizing routes and vehicle utilization, AI systems can reduce fuel consumption and emissions, contributing to a lower environmental footprint. AI can also identify opportunities for using more sustainable transportation methods, such as electric vehicles or alternative fuels, leading to a greener and more environmentally responsible supply chain.

By incorporating sustainability metrics into route optimization algorithms, AI systems can prioritize environmentally friendly options, such as routes with lower emissions or less congestion. This approach is essential for achieving environmental goals while maintaining operational efficiency and profitability. Furthermore, companies can leverage AI to track and report on their environmental performance, allowing them to meet sustainability targets and engage with customers who value environmentally conscious practices.

Enhancing Supplier Relationship Management (SRM) with AI

Predictive Analytics for Risk Mitigation

AI-powered predictive analytics can significantly enhance SRM by anticipating potential disruptions in the supply chain. By analyzing historical data, including supplier performance, market trends, and geopolitical events, AI algorithms can identify patterns and predict potential risks, such as delays, quality issues, or even supplier insolvency. This proactive approach allows businesses to implement mitigation strategies, such as diversifying suppliers, establishing contingency plans, or negotiating better contracts, thereby minimizing the impact of disruptions on production and profitability. The ability to anticipate problems is crucial in today's complex and dynamic global market, and AI provides a powerful tool for doing so.

Beyond simple risk identification, predictive analytics can also provide insights into the likelihood of a supplier defaulting on a contract, enabling companies to adjust their risk assessment and hedging strategies proactively. This detailed level of foresight ensures a more robust and resilient supply chain, reducing the potential for costly and time-consuming crises.

Automated Contract Management

Manual contract management is a tedious and error-prone process, often leading to inefficiencies and legal complications. AI-powered systems can automate contract creation, review, and negotiation, significantly improving the speed and accuracy of the process. This automation can free up valuable resources for strategic initiatives, allowing companies to focus on higher-value activities.

AI can also identify crucial clauses in contracts, highlight potential risks, and ensure compliance with regulations. This proactive approach minimizes legal disputes and ensures that contracts are aligned with the company's overall business objectives and risk tolerance. The ability to automate these crucial processes is a major advantage of implementing AI in SRM.

Improved Supplier Performance Monitoring

AI-powered tools can monitor supplier performance in real-time, providing detailed insights into delivery times, quality metrics, and compliance with standards. This continuous monitoring allows companies to identify and address issues promptly, fostering a culture of continuous improvement within the supply chain. The real-time data provided by AI allows for quick intervention when problems arise, preventing minor issues from escalating into major disruptions.

By tracking key performance indicators (KPIs) across multiple suppliers, businesses gain a comprehensive view of their overall supply chain health. This transparency allows for targeted interventions to improve performance and ensure that suppliers meet agreed-upon standards, ultimately contributing to a more reliable and efficient supply chain.

Personalized Supplier Onboarding and Relationship Management

AI can streamline the supplier onboarding process, automating tasks like document verification and contract negotiation. This streamlined process reduces administrative burdens and accelerates the time it takes to bring new suppliers into the network. Furthermore, personalized communication and relationship building are critical to long-term supplier partnerships, and AI can facilitate these interactions by analyzing supplier preferences and communication styles.

Enhanced Collaboration and Communication

AI-powered platforms can facilitate seamless communication and collaboration between buyers and suppliers, reducing misunderstandings and improving overall transparency. Real-time data sharing and automated alerts can help ensure that all stakeholders are informed about potential issues and opportunities. This enhanced communication fosters trust and strengthens relationships, which are vital for long-term success in supply chain management.

By creating a more transparent and collaborative environment, AI helps to create a more effective and efficient supply chain, leading to significant cost savings and improved overall performance. This is achieved by streamlining communication channels and ensuring that all stakeholders have access to the necessary information in a timely manner.

Improving Customer Demand Forecasting and Fulfillment

Improving Accuracy in Demand Forecasting

Accurate demand forecasting is crucial for optimizing inventory levels, streamlining production processes, and ultimately, enhancing customer satisfaction. AI-powered forecasting models can analyze vast amounts of historical data, including sales figures, market trends, and even external factors like weather patterns, to predict future demand with greater precision. This allows businesses to proactively adjust their inventory strategies, preventing stockouts and minimizing waste. By leveraging machine learning algorithms, these models can identify subtle patterns and anomalies that traditional methods might miss, leading to more reliable and insightful predictions.

The key to effective demand forecasting isn't just about the technology, it's also about the quality of the data used to train the model. Comprehensive and accurate data collection, cleaning, and preparation are essential for achieving reliable results. This includes incorporating various data sources, from internal sales records to external market research, and ensuring the data is consistent and free from errors. Ultimately, the more robust the data, the more accurate and reliable the forecasting model will be.

Optimizing Inventory Management

AI-driven demand forecasting directly translates into improved inventory management. By accurately predicting future demand, businesses can optimize their inventory levels, ensuring they have the right products in the right quantities at the right time. This reduces the risk of stockouts, which can lead to lost sales and frustrated customers, while also minimizing excess inventory, thereby lowering storage costs and preventing spoilage or obsolescence.

Implementing AI-powered inventory management systems can also automate many aspects of the process. From automatically adjusting reorder points to proactively identifying potential supply chain disruptions, AI can streamline operations and free up valuable human resources for more strategic tasks.

Enhancing Customer Experience

Improved forecasting and fulfillment directly contribute to a better customer experience. By anticipating customer needs and ensuring timely delivery, businesses can build stronger relationships and foster loyalty. Customers appreciate the convenience and reliability of knowing their orders will be fulfilled quickly and accurately. This positive experience can translate into increased customer satisfaction, positive reviews, and ultimately, higher customer lifetime value.

Streamlining Fulfillment Processes

AI can automate various stages of the fulfillment process, from order processing to delivery optimization. Automated order routing systems can identify the most efficient shipping options based on real-time data, leading to faster delivery times. Warehouse management systems with AI capabilities can optimize picking and packing processes, reducing errors and increasing efficiency. These automated systems can reduce fulfillment costs, improve accuracy, and ultimately accelerate order fulfillment.

Personalizing the Customer Journey

AI can personalize the customer journey by analyzing customer data and preferences to tailor products, services, and communication to individual needs. Predictive analytics can identify customers likely to make a purchase or need assistance, allowing businesses to proactively reach out with relevant offers or support. This personalized touch strengthens customer relationships and fosters brand loyalty, leading to increased customer lifetime value.

Improving Supply Chain Resilience

Accurate demand forecasting and efficient fulfillment processes enhance supply chain resilience. By anticipating potential disruptions, such as unforeseen weather events or material shortages, businesses can proactively adjust their strategies to mitigate risks. AI-powered supply chain management systems can monitor various factors, from raw material availability to transportation disruptions, providing early warnings and enabling swift adaptations to maintain operations. This allows businesses to be more prepared for unexpected events and maintain stable operations.

Measuring and Tracking Results

The success of AI-driven demand forecasting and fulfillment initiatives depends on robust measurement and tracking mechanisms. Key performance indicators (KPIs) such as order fulfillment accuracy, delivery times, inventory turnover, and customer satisfaction scores should be meticulously tracked and analyzed. Regular reporting and analysis of these metrics provide valuable insights into the effectiveness of implemented solutions and allow businesses to identify areas for improvement. This data-driven approach ensures continuous optimization and maximizes the return on investment from these AI-powered initiatives.

Read more about Real World AI Case Studies in Supply Chain Success Stories

Hot Recommendations

- AI for dynamic inventory rebalancing across locations

- Visibility for Cold Chain Management: Ensuring Product Integrity

- The Impact of AR/VR in Supply Chain Training and Simulation

- Natural Language Processing (NLP) for Supply Chain Communication and Documentation

- Risk Assessment: AI & Data Analytics for Supply Chain Vulnerability Identification

- Digital twin for simulating environmental impacts of transportation modes

- AI Powered Autonomous Mobile Robots: Enabling Smarter Warehouses

- Personalizing Logistics: How Supply Chain Technology Enhances Customer Experience

- Computer vision for optimizing packing efficiency

- Predictive analytics: Anticipating disruptions before they hit